Depends on whether it’s a ‘yip’ or ‘yipe’.

All printers are a little different. I have a Rostock Max V2 with an enclosure. I print PLA directly on the glass. I use window cleaner to remove oils. Head temp 215̊ C, bed 60̊ C. I’ve found all PLA’s are not the same, some 5̊ warmer or cooler helps. Speed 40mm/s across the board, except outer perimeter 30mm/s, and first layer 15/mm/s. Large PLA prints I don’t even try to remove, I let the bed cool and it will pop off. Hope this helps.

What sort of shrinkage are you guys seeing in PLA? I just mounted my steppers, and the M3 screws are NOT slipping through the holes (or settling into the counter-sinks). They are cutting their own threads. Also, the motors themselves end up being pushed back a mm or so, as the offset on the motor doesn’t quite fit into the big hole on the mounts. Is this common, or do I need to spend a lot of time (and filament) calibrating my printer?

On a similar note, I know that a lot of the design is clamping, but I get significant gaps between pieces around the conduit that seem excessive (at least, compared to the pictures of other builds I see).

And on a related, but oddly inverted note, my feet pieces don’t tighten at all on the leg conduit. Even with the screws tightened all the way down, the conduit is loose in the feet (and a couple of the leg pieces as well).

And I get eyerolls and sighs about domestic tasks not getting done whenever I even mention the printer…

There is typically very little shrinkage in PLA and a well calibrated printer should do a heck of a lot better than you are describing. Do you think you’re running into a bit of elephants foot or maybe over-extruding?The 3mm screws should just slide in, no real play and often tight enough that you have to push on the screws for them to go in, but you shouldn’t need to screw them in. The feet should be snug but should cinch up without too much torque on the screws. Time to print a calibration, pick one that’s going to be large enough to measure small errors and small enough to use less than a kg of filament.  (I kind of like the ones that print a 100mm X arm, a 100mm Y arm and a 50-100mm Z tower)

(I kind of like the ones that print a 100mm X arm, a 100mm Y arm and a 50-100mm Z tower)

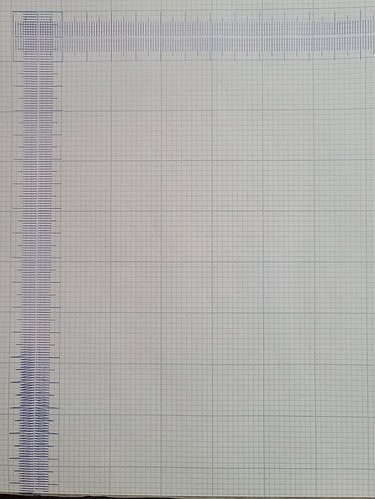

I turned down my bed temp a bit, slowed my feed rate, and re-leveled my plate. A small calibration caltrop (OK, it’s actually a vector, but a caltrop is more fun and alliterative) shows elephant foot on the first layer and something seriously went wrong at the end of the print (looked like the hot end got jammed back through the Z-tower; going to have to look into that some more this evening). Also need to find either my micrometer (went MIA a year or two ago) or my steel rule to verify the measurements. Otherwise, it looks very regular and square. sigh

Groovy… The nickel is supposed to just fit in/through the hole, and my printer runs a closed firmware…

Edit: Ha! Found the M-codes to update the firmware! I can tweak the steps/mm (or is it mm/step?), and hopefully dial it in to perfect prints!

Looks like I was printing at about 99.5% size… I’ll set the actual mm/step tonight, and see if I can’t get a dimensionally accurate print.

Behold my continued necromantic powah!!!

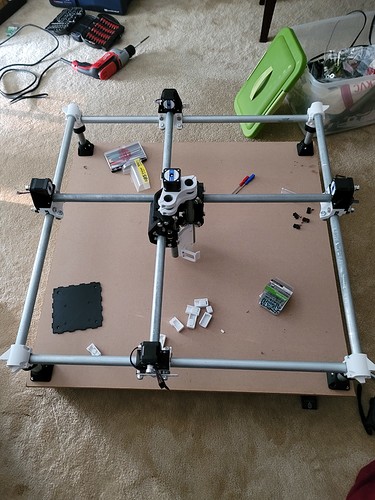

Got an MPCNC-ESP32 board from @buildlog, and a couple of ESP32 DevKit board from the Big Smilin’ River. Built myself a brand-spankin’ new binary of Grbl_Esp32, loaded it up, plugged in a few things, and started moving motors. And making one motor make strange noises… Connectors were all sorts of screwy, had to pull the connectors out of the plug and swap them around. Finally got everything moving smoothly. So, yay!

New controller, new controller lair!

I am getting slowly better at CAD. Not great, but better… No laughing back there! Spent way too long just modelling the damned MPCNC_ESP32 board. GERBER->DXF conversions and all those good things… Thankfully, I could just borrow other people’s ESP32 DevKit and DRV8825 models, and all the little bits and bobs like sockets and headers and terminal blocks, oh my!

Nice buttons. I like how the V1 logos look a little like diamond plate. Do they make custom diamond plate?

I initially had them all facing the same way, and noticed the resemblance. So I flipped one row around… I’m sure someone would make custom diamond plate, if you wanted it badly enough. I’m just going to print it or mill it once I figure out the joinery.

Have to rework most of the parts, and dial in the new filament, but a quick print looks pretty nice.

Ha-ha!

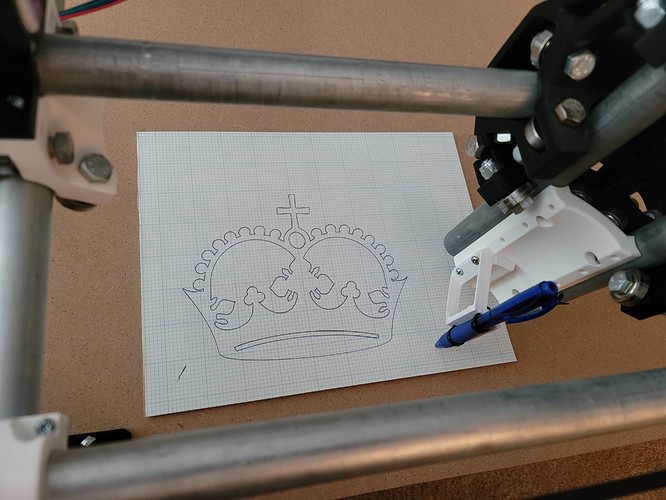

. The day has come where K has drawn a

. The day has come where K has drawn a  . Now sacrafice a

. Now sacrafice a

Need to save up and get a grill before sacrificing meat sources… I’m eyeballing the Weber SmokeFire EX4 2nd gen…

OMG!!!

That is it, everyone, take a vacation our job here is done!

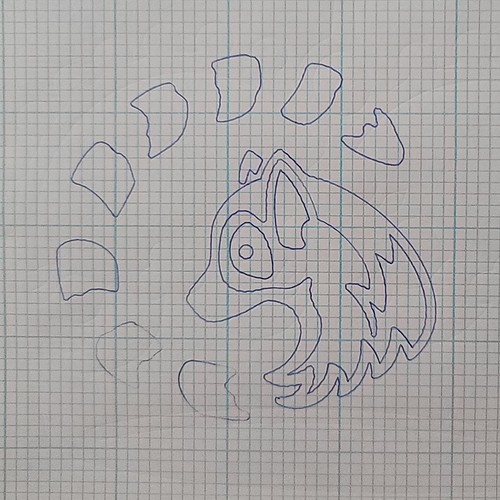

Look upon me and weep, for I am become marginally numerically controlled! The end times are near, and soon Gozer the Traveller will once again return…