Hey guys, I’ve had an issue with my core becoming loose over time… You can see what I mean in the below videos. I’ve had a couple of mistakes where the CNC ended up skipping steps on the x and y gantry’s and I’m wondering if that sort of stress on the machine would cause the core to become loose. That question aside I’d like some advice o how to fix it. Do I need to reprint the 4 clamps that hold the core to the crossbars or does the core need to be reprinted as well?

I would start with just the 4 clamp pieces, and maybe the 4 wedge shaped pieces on the other side ofthe core, and try that. If it works yay! Only after that, would I print a new core.

Have you tried just tightening the clamps up a bit?

Ok, I’ll get those printing tonight and see where that gets me. After posting I was thinking about it more and had the same sort of progression in my head as well.

yeah, I’ve had this issue twice before and I was able to get it to go away by tightening the 8 bolts that hold the clamps to the core.

I would think the other 4 have more to do with it that the other 8?

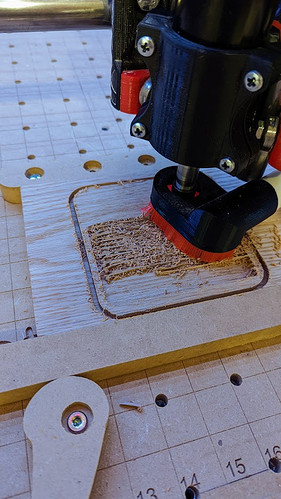

Are you talking about the four bolts that apply pressure to the vertical tubes of the z rail? The videos I show don’t really make it obvious where the play is coming from but it is most certainly not coming from the bearings that contact the vertical tubes for the z axis. I can see the entire core moving as I push/pull the top of the z axis (I understand there is more leverage there). I tried doing a pocket cut of a square back and forth with the wood grain possibly (probably) overly ambitious with the depth of cut and feedrate but the chips that did get cut looked good to me from the research I’ve done. I was attempting a 60% step over and the core would tilt so much that it actually left strips of wood uncut but I thought it was surprising that the cuts themselves seems surprisingly smooth there was still audible chatter though.

No… I think he’s referring to the 4 vertical bolts through the clamp pieces that you start with being as loose as possible and only tighten when the bearings aren’t making good contract with the rails.

Edit: Somehow I never even considered that someone would get to the “reprint parts” stage without trying this first… By the way… I would slightly loosen (1/4 -1/2 turn) the bolts holding the clamps to the core first, tighten the vertical bolts, then tighten the core bolts back the same as I’d loosened them.

Hmm I guess when I think about how those clamps apply pressure I thought that tightening the bolt holding the bearing in the clamp would cause them to become looser because your pulling the bracket together which I was thinking would result in the bearing being pushed further from the core… I’ll give that a shot and see what happens. I might have to reprint the 4 brackets. I didn’t notice till this morning that I printed them with 15% infill . . . but I had a .6mm nozzle on with 3 to and bottom layers, 2 perimeters so the shell of the part is pretty rigid lol

wow, I’m thoroughly surprised by how big of a difference that made!! I can’t wrap my head around how that would tighten everything up but it totally did lol I really hope I don’t find myself needing to tighten it again but if I do notice some play in the core would I start with the 4 bolds holding the bearing in the brackets again followed by the bolts that hold the brackets to the core? (hopefully it just doesn’t loosen up again and it won’t matter)