Fair enough, I suppose that some more info on my background and experience is in order.

My first 3D printer was maybe 6 years ago, I bought an I3 kit which was complete and utter crap. But I learned a lot trying to improve it. Eventually that hit its limits, and I wasn’t very happy with it. Then I bought a somewhat better kit. It had a bunch of proprietary parts in it, and again, I went through the upgrade and repair cycle with it.

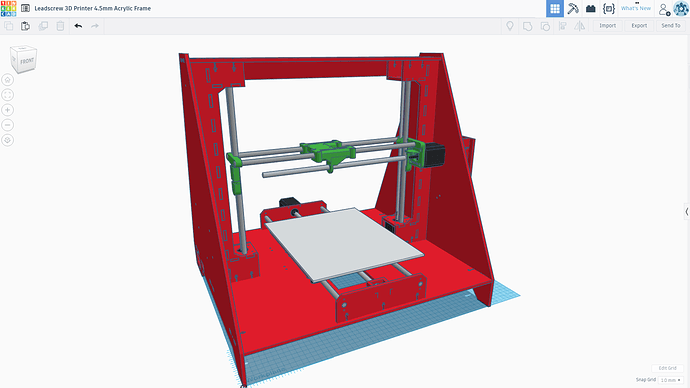

Then I designed and built my current printer. (In TinkerCAD, which was a mistake, but it was the tool that I’d learned well enough to do it.) I’m quite happy with it, and it uses parts that I can easily replace. In my workings with previous printers, I had (incorrectly) identified the belt drives as a source of problems, so my design was all leadscrew based. It actually works very well, but I’m in the process of redesigning based on CoreXY, now that I have my Primo. The design looks like this:

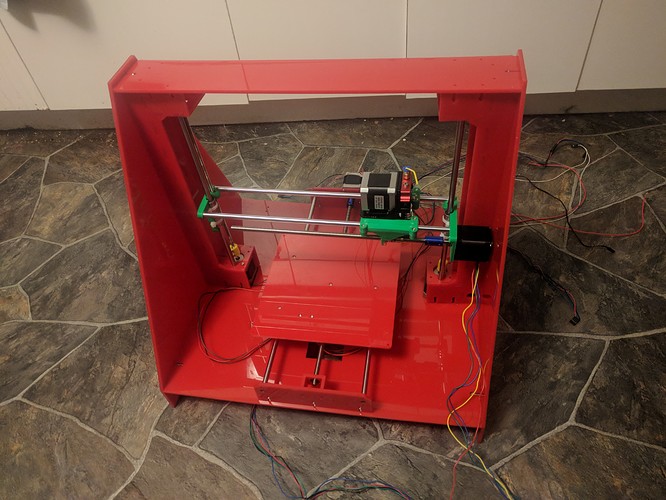

The actual machine: (Assembled, but no wiring, heated bed installed etc.)

Sometime in this period, I bought that GRBL 3018, and started trying to learn the CAM portion of its use. I obviously made some miscalculations there, and the result is a busted Z axis on a cheap machine. I’ve sort of repaired it a couple times…

I’m reasonably confident in my 3D printing skills. I kind of think that I can make TinkerCAD sit up and beg, though I realize that it is an inherently limited platform. Other hobbies that I have are my car. I built the engine from a bare block up. The block was sent tot he machine shop bored for forged pistons, and I set it up with a rather oversized turbocharger, and making more than double the factory rated power. I also had another Supra that I had set up as an IASCA (International Auto Sound Challenge Association) competition car, competing in the Sound Quality division for three years. It featured a fair amount of fibreglass fabrication in the hatchback and in the doors, and more than a little electronics customization. I also built my home theatre system. The amplifier designs came from the Internet. Well, more specifically from Rod Elliot’s web pages, but I made and populated the circuit boards for the pre-amps, signal processors and amplifiers. I selected the drivers, and designed and built the speaker enclosures. (And after breaking a basement window, vowed never to turn the amplifiers past “3” ever again.) Also in the home theatre, my projector is of the DIY variant. It uses a small WUXGA LCD screen and controller, and a 400W metal halide lamp to project a 144" diagonal image on the wall.

I’ve been around woodworking shops for most of my life, my father was a carpenter and general contractor. I’m a computer programmer by trade. I’m sure that I could design and print a new Z axis for this machine, and either salvage the bearings and rods that it’s using, or just grab new ones from my parts pile. I have some confidence in my fabrication and design capabilities. The original purpose of the 3018 was supposed to be circuit boards, but of course my most recent design calls for 24x24cm, which it can’t do, though the Primo certainly can.

SO, what I’m looking for is ideas. I actually like the idea of devoting a machine to edge joinery. The tricky part there is going to be designing the machine to clamp the part. I’m considering some ideas. I’m always open to more. As you can see, it’s not like I wouldn’t have a use for some specialty machines.

The local makerspace might like it, sure… Except of course they’re currently not allowed to meet because of the pandemic. They have Most of my old I3 in their spare parts bin. I think someone was turning it back into a printer. I wish them luck.

Anyway, this is me. The man with too many hobbies.