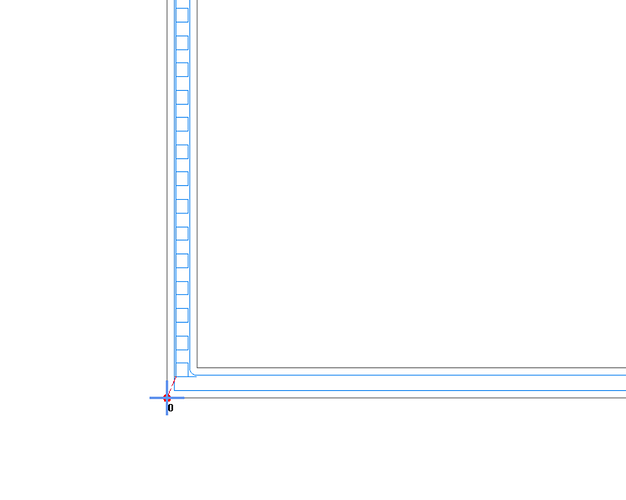

I was making some test slots in the X and Y. I drew up a 1/4" slot in each axis and cut them. I test fit a piece of key stock and the one cut along the Y axis was much tighter than the X axis. I also found it odd that Estlcam took a different path on the X vs the Y. I wasn’t sure why. Is this normal?

When Estlcam clears a pocket, the strategy that it takes is determined in those settings. For the "linear

pocket strategy, it also asks what angle you want to do it at. At 0° it makes the clearing cuts horizontal. If you changed it to 90° it would make them vertical. 45° would slot them so they looked more similar.

A little variation is maybe belt tension, but also some flex in the machine will do it. The machine will flex differently in the X and Y in this case because the pathing is different. This will have a small effect on the finished cleared area. A little more material will be left by the back and forth pattern for the final clearing cut.

Having a finishing pass will help with this, where it removes a tiny amount of material in one last pass over the work.

Thank you for the clarification on Estlcam. I thought maybe I had something else wrong. Is there a recommended angle to use for the lowrider or a reason to use different angles?

I would use a finishing pass if you want precise (fitting) results. If you enable the finishing pass, the roughing pass leaves 0.1mm or so of material and then comes back and makes another pass at exactly the right spot. The second pass is full depth, and you can just barely hear any cutting. Nothing should be flexing at that point.

I would probably want to align my pockets with the X axis (the single belt axis) because there is less moving mass.