I build a low rider with a mini-rambo board. I use Estlcam for gcode and repetier to run the cnc. Cnc machine setting are off on z steps. Cut was to be 11 mm but only cut less then 2 mm and also when I manually move the z steps I have the same problem. I don’t think the problem is in Estlcam since the manual controls are off. The x and y work fine. I had to upload the V1CNC firmware since the firmware did not word the board when I got it. How do I make the adjustment.

Do you have T8 leadscrews with 4 starts? I am guessing you’ve got 1 start screws, which need 4x as many turns to go the same distance.

You can adjust the steps/mm. I think Repetier has a menu to do that. They should be at 400 for a 4 start. It may need to be 1600 for a 1 start. When you do that though, the stepper will need to move 4x faster, so you can only go 0.25x as fast, or maybe a bit faster. So you might also want to drop the max Z speed to about 3-4mm/s.

I’m using 5/16 lead screw. Will I still need to do as you stated ro do the # need to change.

Oh ok. On a low rider?

I think that should be really high then. 2250 or so.

Thanks I’ll try that

I could not find any adjustment for the steps/mm in Repetier. I think might be in the firmware on the board.

It is, but I thought there was a menu in repetier host that would let you change those settings. No big deal.

If you use the send gcode thing, and look at the console log in the bottom you can set it yourself.

M92 with no arguments will print what you have it set at.

M92 Z2250 will set it temporarily. You can then jog around and see how you’ve done. Make sure you move as far as you can to get as good of a measurement as you can.

If you like it, you can save it with M500. Otherwise, power cycle Marlin and it will reset to whatever you saved it to. When you get something you like, don’t forget to write it down.

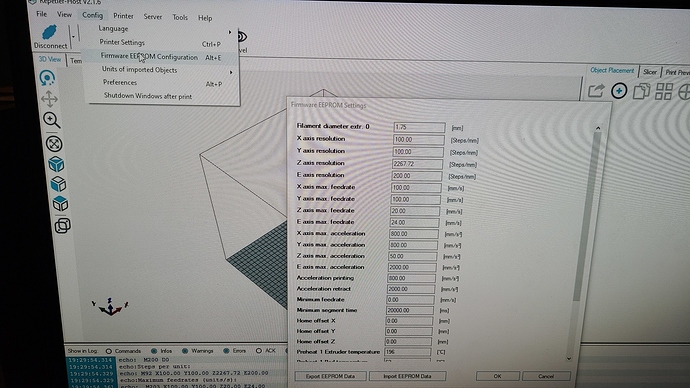

Config>Eprom Settings

I don’t Config>Eprom Settings in repetier. I tried m92 z2250 and all it did was move the gantry all the way down to the with the wheels off the table.

would I be better off getting the 8mm lead screw with 4 start

I order the 8mm lead screw with 4 start . I didnot think there was that much different in the screws.

Sorry, I just got home to check. It’s Config>Firmware EEPROM Configuration.

Edit: Funny enough, the Z axis resolution is the one you need for 5/16 all-thread. Thats what is used on the Piper printer I run from this.

Very odd. It is case sensitive.

That option i grayed out on both computers that have the program on

Are you “connected” to the board when you try to select it?

I checked and found out the board was not powered up. that worked then turned it on. Thanks.

Sure man! Hope you get everything squared away. Glad I could help.

Thanks that was a big help. I am still going change out the lead screw. I think that one the 5/16 screws is damaged because one side does not go down when it running the program. It makes a noise like the motor is stuck. I changed out the motor and it did the same thing. I hope the new lead screw solve the problem.