So since we got the same trimmer…have you found a 1/8" collet for it?

No, I’m using 6mm and 8mm bits (easily available here in Europe)

Elaire sells the precision collet for the Makita. I used a 1/4 to 1/8 collet adapter for a long time though, worked fine, added run-out was minimal.

Is there any particular reason for the size of the holes to have so much variation? Besides the screws that fasten the makita, of course.

[attachment file=103303]

Nope just sloppy CAD, inconsistencies.

Are any of them causing you an issue?

No, just asking before cutting the Y plate

Hey guys, just throwing this out there. If the carriage can touch your workpiece when it’s all the way down, don’t let the router collet stick out the bottom. If for some reason the rambo loses power the carriage will drop. If it’s just the endmill sticking out, it will drill a hole through the work and into the table. If the collet is sticking down, the endmill still drills through everything, then the collet hits and starts a friction fire.

Hi Frederik, I wanted to ask you if the files to print in your version for the makita chuck named “Hose Bracket, Hose Bracket Mirror” are for the lowrider 2 25mm version to replace the original"Hose Bracket 25, Hose Bracket mirror 25" . I also wanted to ask you if you have the VacDuct_Makita.stl file printed in pla or petg

Anyone who can help me understand what I wrote in the message above?

As mentioned Elaire has 1/8" and 1/4" collets for the Makita. I bought e set from them with 1/8", 1/16" and 1/4".

Quality seems good

I’d like to know if the plate fits for 25mm tubes too…

Anyone has feedback on whether this will work with 25mm tubes ? From what I can see the major area of concern would be the bearing holders screw holes that might be slightly more closer

I’ll measure the spacing with a CAD tool, but since measuring on imported STL files is a little bit of a pain, a formal answer would be very helpful.

[EDIT] Silly me, I just need to measure on the DXF directly. From what I can see hole placements are identical, so it should be good to go. I’ll print it and test, since I received all parts for my LRV2 build

Yes, I have a 25mm LR2.

I’ve just tested the fit on my Makita RT07000C: In my case too the red push-button “bulge” is not well aligned to the recess in the VacDuct part. There is approx. 2.5mm clockwise difference on the verticals from the center of the button to the center of the recess in the printed part. @frederik: would it be possible to publish a version where the recess is rotated more towards the back? My CAD skils are not up to this task

The fit of the VacShoeTop is close to perfect. My printer didn’t produce crisp corners for the 2 small locating tabs and I had to file the corners a tiny bit but otherwise no issue!

I ran into a similar problem with a power.supply case and switch I used my dremel and a sanding drum then by hand and file not a elegant fix but serviceable

@charliefd Would you mind trying the attached file instead?VacDuct Makita rotated.stl.zip (242.3 KB)

@Frederik: it is now centered! Thank you!

A perfectionist would say that the recess could be slightly wider to match the slope of the router protrusion: the angled sides of the “bulge” hit the top corners of the recess before the rounded part touches the bottom. But I’m quite happy with it  , in fact I clamped the router a bit higher so there is no touching involved

, in fact I clamped the router a bit higher so there is no touching involved

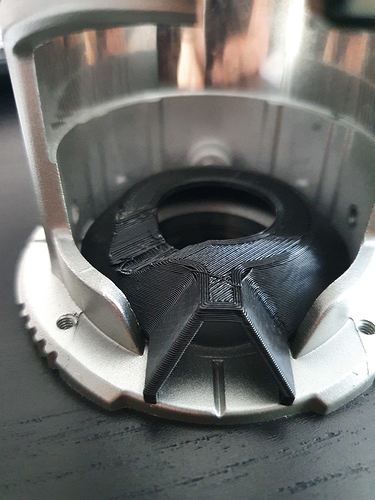

Symmetric and beautiful:

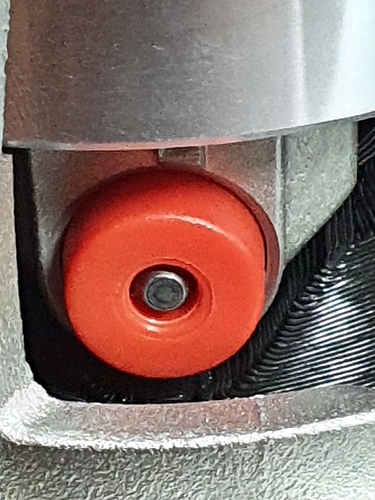

Touching top corners:

Raised a milimeter or so:

Luckily changing that is quite easy with parametric CAD. I wonder why I didn’t notice this - maybe they changed the design of the router a bit.

Anyways I’ve attached a version with wider chamfers that should fix this problem.VacDuct Makita wider dent.stl.zip (242.1 KB)

Wanted to upload this to Thingiverse, but it’s throwing errors (again).

@frederik I’ve just finished printing this new part, dry fitted on my Katsu (Makita clone) and everything fits great…redoing the base plate…so testing will have to wait a few more hours…

One question what are the hose brackets for?

Thanks for sharing your work.

Àlex