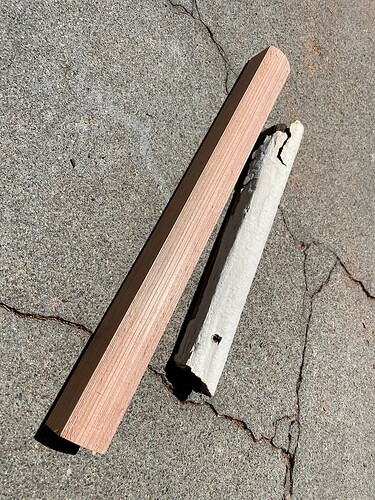

Nothing too special, just a quick and dirty job to make some ‘hard to find’ exterior trim that I will need to finish a dryrot repair job on Monday. The trim fits around a wood octagon shaped gable vent on the house, as well as the garage door casing. The 16" long pieces are long enough to replace the gable trim and patch the rotted lower portions of the casing.

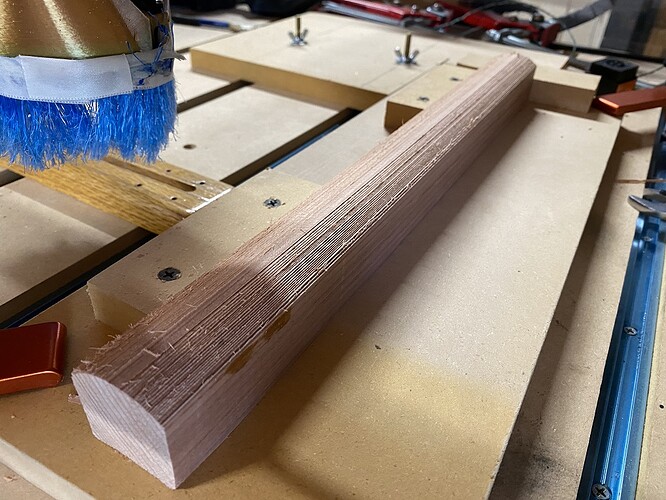

This was my first job with redwood. It cuts very easy, but it’s stringy like Mohogany. I ran 80ipm, 0.15 doc, 0.25" stepover, with a CMT 1/4" 2-flute upcut for roughing… finish pass with the same bit was at 200ipm, variable doc/stepover contour with 0.05 max doc and 0.12 max stepover. One of the pieces I cut was so stringy that a packed clump of spaghetti like chips managed to completely clog the vacuum attachment. I had to pause the job, pull the clump out from the attachment, and continue the cut.

I should have switched the cutting order from bottom to top, but I just wanted to get it done fast and there was only one clog cutting from top to bottom. I found cutting bottom up on thin contours like this seems to keep the stringy chips under better control.