I’m fairly comfortable with using estlcam now, but I can’t quite see how to cut a hole into wood where the sides are not vertical. I’d like to cut an inverted (capped if it matters) pyramid, so the cross section changes as I descend.

Is there a way to do this in estlcam, or do I need to create my design in some other software? I mostly do 2d work with a little 3d, but don’t generate the 3d files myself.

You need to make that shape in CAD and then export as an stl. You can then import the stl into estlcam and it will CAM it. It may not be the most efficient way to cut an angle, but it doesn’t really know what you’re cutting, so the algorithm it uses works for any shape.

Take it slow. CAD is a profession as well as a tool. So most powerful tools are focused on the user who spends 40 hours/week designing and there are a bunch of ways to do something. You won’t be able to learn everything at once, but know that anything you learn will be helpful.

Also, enjoy it. If you can stick with it you will end ip with a bit of a super power to be able to just take something out of your head and test it out in electrons. You can really do some amazing things in CAD. It is underappreciated, honestly.

Don’t stress too much about which program you start with either. Something like onshape is free, and doesn’t require any installs. Fusion 360 is also free, but needs and install in windows. Tinkercad is easier. So is sketchup. Skills learned in these tools are mostly applicable to other cad programs.

FreeCAD is another great option

So, following on from this.

I have been wondering about cutting slope/angles into a piece of plywood for a face joint sort of thing.

Here is a picture of what I have in mind.

So the back is flat, but the edges are at a slope.

Is it possible on estlecam to

- import it as a .stl file

2.cut out the slope as a 3d job (sort of how I think of it)

3.then cut out the perimeter just like a normal piece of plywood with tabs?

Puzzled.

I have never setup the post processor on Fusion. I had a go but it got too deep and dark for me.

What would you suggest?

This is to make an anchor well in the deck of a boat. I was thinking I could just draw it with the pieces touching on their corners, derive some custom angle brackets in Fusion from the model, print them on the Prusa and use them to hold it together while the epoxy set. Then remove them and cover over the gap with more epoxy.

In other words so as to avoid the 3d milling of the angled edges.

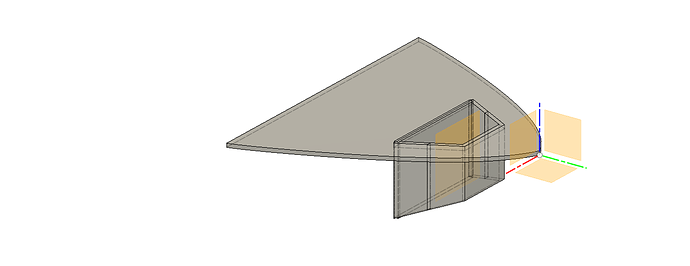

Here is a rough sketch of where I am heading.

As you can see, I am not a 3D designer…

Rob

If your just trying to put a simple angle on each side, I would use a saw rather then a mill…

Well, that is of course an option but was sort of trying to extend things a bit mentally.

I have watched the Estlecam youtubes on the 3d bit but sort of not getting it.

Was trying to get away from tabs and things.

R

Just from my understanding it is pretty difficult to get a nice angle, you would need to use a v bit I think or you will end up with a bunch of steps rather than a smooth angle. And it will be slow to cut.

But maybe I’m wrong, I’m new to milling myself.

My thinking was to cut the angles, and steps would be fine, then epoxy/glue the anchor well together.

So the steps aren’t really a problem as they would be full of epoxy.

Shell just have a go and do some cuts in midair and see what happens I guess.

R

(all good fun)