Does anyone else’s DeWalt 611 collet get very hot after short (~20min) cuts? I just noticed this after attempting my first cut with a bit change in the middle.

Heat creep from the motor.

I take it that it’s not an issue long term?

Nope. I’ve run mine for almost a full day, 20ish hours straight. No issues.

There is a lot of factors that could cause your “hot collet”. 1 - bits dia… comes into play big time. 2 - Cutting speed combined with cutting depth. 3 - Router RPM and 4 - Material being cut. Trim routers are not designed to be ran hard for long periods of time. They are designed for light duty, work. That said, yes you can run one for a long period of time provided you’re not using a 3/4 inch dia straight bit, making a 3/8" deep cut at max rpm through black walnut.

I come from a woodworking background, got into using CNC as just another tool. Most other CNC users are using these small 1/8 inch (or less) dia bits, that don’t take much to power them.

Here’s some tips that might help.

- NEVER push the bit all the way up into the collet. Push it in and then back it out a couple of hairs. -- This will prevent the bit from locking up inside the collet, or making it impossible to removed until cold.

- Look at the bit you're using --- dull bits need sharpened or replaced as they build heat, make the motor work a lot harder, and give make crappy cuts.

- Match the bit size to cut depth. Yes, i have taken a 3/4" 1/2" shank 1 1/2" long straight bit and cut through 1 1/4" white oak in a single pass... but it was done with a 3+ hp motor and cutting very slow... and on a bet that it could be done without burning the wood or bit. :)

Good luck and have fun.

P.S. One other thing that can cause the collet to get hot quickly is a loose bit. Is the bit isn’t 100-percent tight, which is much more than finger tight… it could be catching the workpiece and that friction will make the bit and collet very hot, very fast.

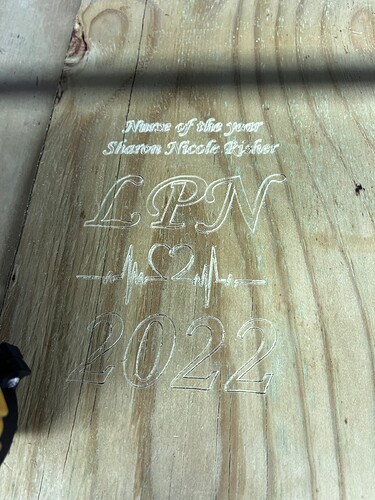

I just did this carving for my wife on some normal 3/4” plywood scrap as a test run and it took about five or ten minutes or so and the bit wasn’t even cutting that deep, maybe an 1/16” or so and it got supper hot. Is there any way to help the cullet and bearings cool.

Hrmmm… Hot Collet… Sounds like a nutrition-neutral, hand-held, microwave snack for the on-the-go machinist!

I had a similar question since months ago. Running it over speed 3 seems to help. Not sure if it’s an actual problem, but I did smoke one of my routers and I think these are probably expected to run 10 or 15 minutes at a time.

It makes more noise at full speed, but the fan pushes more air. Everything I read and heard lead me to just run it full send and up the feed rate appropriately.

Mine isn’t variable speed it’s all or non.