Here’s a project that highlights one of the reason that I built a drop table for my MPCNC.

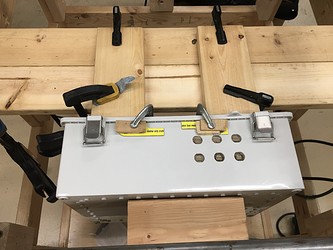

I needed to cut some holes in multiple sides of an ABS junction box that I purchased for a work project. The overall box dimensions are 350mm x 270mm x 150mm (14.6” x 10.6” x 5.9”).

I dropped the table about ~150mm (~6”) for the first operation

and bored out the E-Stop hole.

I then removed the elevator board from my table (to get a more stable mounting surface in the next areas to be machined), clamped the enclosure down to the table with a few 1x4 boards and machined the aviation connector holes.

I then rotated the enclosure 90deg

and cut the intake fan opening.

Finally, I rotated the enclosure 180deg and machined the power, exhaust and USB openings.

Here’s the fully machined box.

And this is the final assembly with all the electronics installed (still need to clean up the cables a bit and add the drivers.