Results of my final experiments.

After going through the machine, moving the legs to take out some bind, changing the belts, checking bearings, looking for friction and play, I performed a squaring operation using 2 x 24" machinist scales set up in a cross pattern.

I needed to cut some parts in aluminum that will be rotating so at least need to accurately make some centering holes for later drilling that are within .2mm positional tolerance or better So unloaded movement accuracy is priority and cutting a roughly 100mm circle needs to be close to the same but not as critical.

So my thought was to cut some 300mm circles in something that could be rotated and checked for runout. Best thing I could find was 1/2" thick pvc sheet. It gave a relatively smooth cut finish that I could hit with some 220 sandpaper and get a good measurement. Then I realized 300mm was not cost effective so I switched to 150mm circles. This should give a good indication of machine+cut+flex accuracy.

My initial cuts as described above were with 1/8" kyrocera single flute endmill at 5mm depth, 100% width at 1400mm/s feed rate. Finish cut full depth with 900 feed. I recognized some variation in the cuts and was still around 0.25mm runout. For my final runs I moved to a 2mm cut depth and 1800 feed. This took additional load off the machine and reduced the variation.

I

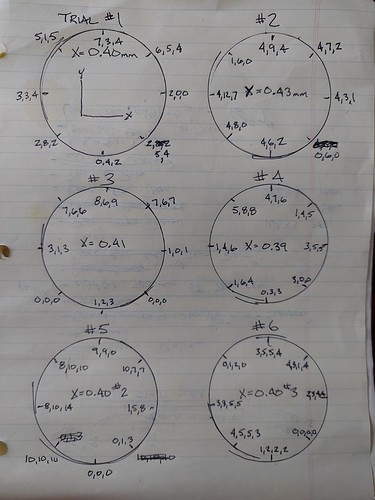

Trial #1- My programmed offset is X=0.40mm. Trial #1 is with that offset. I found that depending on where you measure runout on the .5" cylinder, you can get a slightly different result so I began taking 3 readings. All are in thousands of an inch (2=0.002").

Trial #2- programmed offset X=0.43mm. This resulted in some higher numbers in the diagonal from origin so I thought I went too far.

Trial #3 - X = 0.41mm, this definite shows some higher numbers on top half of circle. Not sure what that means but they were worse than Trial 1.

Trial #4- X=0.39mm. This was no better than Trial 1 either and looks like the top left to lower right might have gained.

Trial #5 - repeat ot Trial #1, X=0.4mm. Definite higher numbers than Trial #1 most of circumference. Since the original numbers were not repeated I began searching for play in bearings. I tightened up the core bearings where I found just a little movement.

Trial #6 repeat trial 1 and 5, X = 0.40mm. Equal to or better than Trial #1. Max out of round is 0.005". Most consistent results on different levels of cylinder. I took 4 reading here.

Summary

1 Accuracy and repeatability unloaded is extreemly good, better than I can measure.

2 Accuracy and repeatability when cutting depends on tool loading. If you need accuracy, you want to run the lightest tool loads you can stand.

3 machine needs to be in tip top shape. I have mentioned this before. Lock the motors, grab the core and try to move it. There should be no rocking of any kind, just a gradual stiff spring like movement as you press harder. In all x/y directions.

4 cutting circles is no better than squaring with scales. If you are truly worried you cuts are moving after checking over the machine, then you can cut some to verify. Measurement variation can be up to 0.003" on my small circles. A larger circle would obviously be better and more representative. I don’t know of a cheap material to do this with. I may run another before I start a critical job.

5 I am not sure this will translate to an aluminum cut, but will post results. As long as I can centermark holes for drilling accurately, I will be ok.

6 Best method of squaring machine so far is machinist scales.

Thanks to everyone for the inputs. I hope this helps the community.