Spoken to likeminded mates, watched a few how to videos and I have finally taken the plunge. Below is my setup (For now ![]() )

)

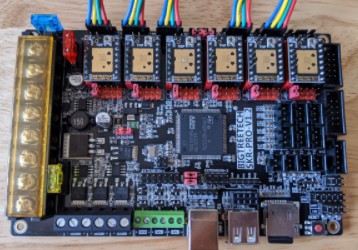

There were a few hiccups along the way. I am onto my third skr pro v1.2 board. 1st one (from V1 engineering) was me not watching what I was doing and never realised my child put a pot lid under my board. So school fees paid on that board.

2nd board finally arrived (aliexpress) and it was faulty! couldnt read the sd cards or communicate over usb. So that one was replaced.

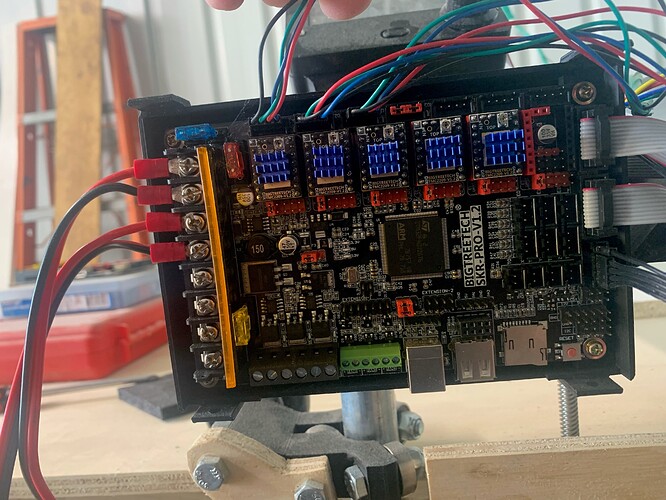

3rd one (ebay) looked like all was ok. UNTIL I noticed a stepper driver not working. Replaced the lot just in case. So the below is what my board looks like now.

I am able to move X and Y but not Z. I tested Z motors in Y slot to make sure its not cabling or motors. All ok there.

I ran m119 through pronterface. and got the following results:

m119

SENDING:M119

Reporting endstop status

x_min: open

y_min: open

y2_min: open

z_max: TRIGGERED

z2_max: open

z_probe: TRIGGERED

So my mistake from my first board has now led me into issues which I dont know how to fix.

firmware I am using is V1CNC_SkrPro_DualLR_2209-2.0.7.2-src

Anyone able to help with a bit of advice to resolve or check?

will update as I go ok.

will update as I go ok.