Upsss, Thank you, I think it is now corrected

Whoa! That is super fun. Nice work.

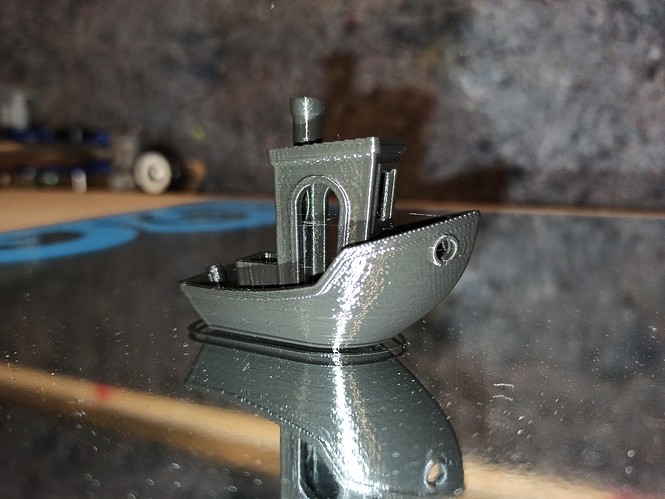

Second print test with the lowrider. I have to say that I am very satisfied with these first tests, I didn’t expect such good results. It has nothing to envy to my Ender 3 printers.

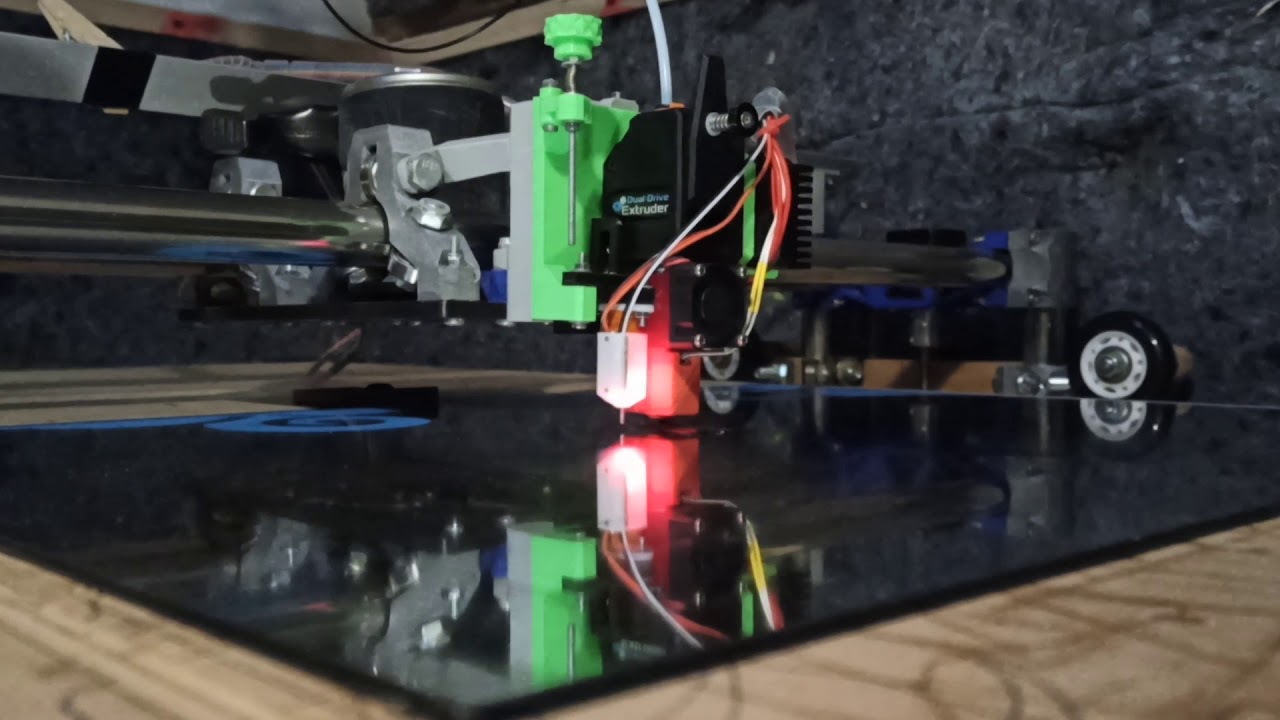

The BLTouch is already working, i had no choice but to physically install the end stops to the X and Y axes in order to get the bed leveling (G29) to work. It is wonderful to see the LR doing this operation. So I’m ready for when I get my silicone hotbed.

I have a to-do list on this project:

- filament runout sensor

- a layer fan

- filament spool holder

and most importantly, and part where I’m stuck, after installing the BLTouch (which I’ve plugged into z_min) I’ve lost the ability to use my touch plate, so now I don’t know how to probe my materials when using the LR as a CNC.

I have seen MPCNC working as 3d printers, I don’t know if anyone has installed BLTouch and encountered the same problem, and if so, have you managed to solve it.

At the moment, I am forced to change the firmware every time I need to use the machine as a 3d printer or CNC (but it is very tedious).

I am aware that wanting an all-in-one is sometimes a chimera, and if there is no other choice I will continue to make the necessary firmware changes to have this multifunctionality, not that I will be printing very often, but there will be the possibility.

Any idea / suggestion is welcome.

Regards

Roger

Why can’t you use the bltouch when probing materials? Is it just a mount problem?

Hi Jeff,

The BLTouch is attached to the 3d print head, and set in marlin so that the Z offset with respect to the nozzle is correct. I could mount the BLTouch outside the head (somewhere in the frame), but when I use the machine for milling jobs each bit I mount will have a different offset with respect to the bltouch tip, and I don’t know how to solve this, that’s why I thought to keep using the conventional touch probe as so far, but with marlin set for BLtouch when I connect the touch probe it doesn’t work, I send G28 Z and it doesn’t make any movement. This with the BLTouch disconnected from the electronics completely and connecting my conventional probe to z_min.

A Duet3d forum user had the same case as me. He managed to solve it, but his solution from what little I have investigated is not applicable in marlin.

Ah, of course.

You could separate the logic of the probe from the logic of zmin.

There is a config like Z_PROBE_USES_ZMIN that you can turn off. Then set the z probe pin to any pin. At that point, Zmin will be used when homing G28 but not when probing G29.

That’s not a great choice for 3D printing though.

Maybe the problem has more to do with the bltouch logic being inverted from the touchplate. Maybe you could invert the touchplate signal somehow to get it to reverse.

Can’t wait, thanks for the ideas, I’m going to the workshop to make those changes and report back with the results.

Thank you very much Jeff

What I want to know is how is everybody able to print on un-heated glass and have the prints not come un-stuck!? Is there another incantation I’m missing?

Ahh right, the glass didn’t look like there was anything on it.

For your probe issue, you need to change the firmware why? I understand why you can’t use the bltouch to probe for cnc but can’t you just plug your probe plate into the z min pin and probe away? I’m pretty sure you can change the z probe offset via gcode. And doing so wouldn’t save it permanently, so just add the offset to your start gcode in your slicer. Or am I missing somthing obvious?

Hi Atom, i thought so, but no. I had it working that way and I had the probe working just fine, until the BLtouch was defined in marlin and the BLtouch works, but the probe does not (both connected to z_min).

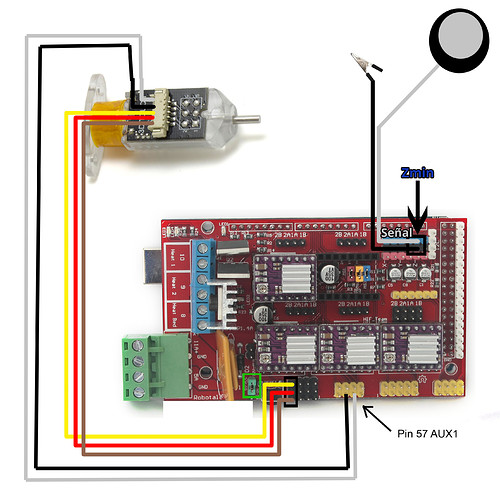

Jeff, I had no luck, not sure if I understood you correctly. Now I have configured marlin to use the probe connected to z_min_endstop (as usual) and the Bltouch instead of connecting it to z_min_endstop connect it to another pin (pin 57 of aux1 was the one I tried). As a result the probe is working again with the G28 Z command, but the BLtouch is no longer extended/contracted on the G29 z-probe.

Since a picture is worth a thousand words, I’ll make a little diagram of how I have it all connected:

In the firmware I have made these changes:

Blockquote

//#define Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN

Blockquote

#define Z_MIN_PROBE_PIN 57 // Pin 32 is the RAMPS default

Attached are my configuration files for more details.

Configuration_files.zip (73.4 KB)

Regards

Roger

That’s what I was suggesting. I wonder why that didn’t work… Darn. Does M119 show a Zprobe?

Have you tried leaving the bltouch plugged in? I wonder if when you define the bltouch in Marlin if the board expects some sort of feedback during power on confirming that it is working properly(at least on my bltouch it sets there and does some sort of boot extending and retracting itself a few times, I wouldn’t think that gives any feedback to the controller but maybe it does?)

It was working since I made the changes you suggested Jeff, but I thought it wasn’t working because ordering G29 automatically precedes a G28, and I have to keep in mind that in that G28 the z polling is done with the touch plate and not with the BLtouch sensor, once that G28 finishes it does start doing the bed leveling. Fantastic, thank you very much, you found the solution the first time.

Thank you very much to both of you.

Don’t give me too much credit. I vaguely sent you into a corner. The work was all you.

There is also a G38.2 command you can enable, which will let you use the probe to judge Z height. But I don’t think it actually sets anything. So you’d need some homing gcode magic like this:

G28 X

G28 Y

G38.2 Z0

G92 Z0

G29

That whole macro would need to be set in your gcode controller. But then ideally you could use that and not use the touch probe.

Great print results, kudos!

Maybe that’s a stupid question, but why don’t you just get an other BL touch and install it on your milling tool?

Sure they are a bit expensive but that would probably save you a lot of headaches.

(edit: sorry I haven’t seen that the problem has been solved already)

Hi Jeff, i was unaware of the G38.2 command, but the worst thing is that my marlin also seems to be unaware of it:

G38.2 Z0

SENDING:G38.2 Z0

echo:Unknown command: “G38.2 Z0”

Working with Marlin 425 D 2.0.5.3

![]()

that wont help much with different tool lengths, the probe offset would always be changing. might use one bit that sticks out by 12mm and another that sticks out by 14.5… that is why you want a touch probe… that said you could print on an aluminum plate and just use a normal touch probe for printing XD.

There is a config parameter to enable it. Something like ENABLE_G38. or some similarly clever name.