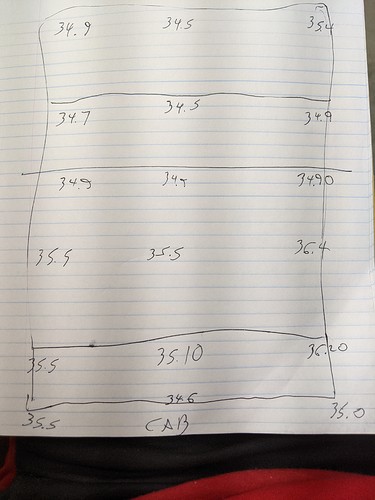

So I have my lowrider up and running. I have been trying it out by cutting some straight 2d door panels for a camper van I’m remodeling, but I want to start doing some 2.5d signs, etc with it. I noticed when looking at my waste board and the cuts as the gantry goes along, that I am more shallow in places than others. I used a piece of plywood and moved the gantry to different areas of my table. It’s a ping pong table, so it’s 105x60. The numbers are what I got when I touched the piece of wood. What is everyone’s opinion on these numbers? Are they within decent spec for making signs, etc? I’m not trying to build precision parts but I want things to look right. I know it may be a matter of opinion, but I wanted to see what you all thought about the variances on my table.

A variance of 1.5mm is a little more than you want, but still reasonable for 2D cutting.

For 2.5D, you’ll probably find that those those projects tend to be a little smaller, and will probably fit into the area where you have variances of .5mm or less. If you need something larger, there are other methods that you can use.

I have a couple of projects that are very depth sensitive. I use a foam block, which I surface first. This can be done very quickly, and leaves something that the machine will see as perfectly level. In your case, a single 2mm DOC pass is enough to ensure that the whole surface will be level. Easy. If it’s a regular need, you can surface the whole spoilboard.

That is great advice concerning the surfacing of the board. Right now I have been using a piece of melamine that I had left over from making shelves as my waste board. Is there a special big bit you use to do the surfacing with?

I have a 1" surfacing bit to make the job faster, particularly with foam. Doing the whole LR2 table with a 1/4" bit is lol.

I found that the trick seems to be going fast enough. This one likes to scorch the surface a little if it’s too slow.

I think 1.5mm is pretty good. I doubt you will notice a pocket being 1.5mm deeper somewhere. But a 90 degree v but will be 3mm wider if it is 1.5mm deeper. A 45 degree would be less. V bit over 60" isn’t a fun job to watch though.

Also, on big signs, you should try to male them by layering up thinner pieces of cut out pieces. Pocketing even one square foot takes forever. It is much faster to cut out a letter and glue it to a background.

Id investigate your right hand side a bit it looks like your largest variance is there between the table split. Same thing with the left side to a lesser extent. If you can shim those a bit closer it might be acceptable even without the surfacing.

Also I’d question whether your measurements are simply mirroring your floor irregularities. If you rotate the table 90 degrees do you get the same offsets?

Edit: it looks like you have 2 flat tables both with a dip in the top right corner but that aren’t coplaner. Maybe just equally shimming the legs on the lower one would fix it.

Michael, you are right on the shimming part. Before I took these measurements, it was a lot worse. With it being a ping pong table (even an expensive one as those things go), there was still quite a bit of variance. The measurements I posted are after some shimming. I was hoping that I was getting close enough to quit trying to cut different size shims for the legs. I guess I may still have a little bit of work to do. I am sure I have irregularities In the floor also. You are probably right about moving the table to a different area also, but I think where I have it is where its gotta live to make the wife happy with being able to get at least one car in our 3 car garage. I am thinking maybe one more night of shimming and a surfacing of the wasteboard hopefully would clear up any issues.

Thanks Jeff for the idea of complete cuts and stacking vs pocketing deep areas.

Dan, I got me a bit delivered today from amazon to do the surfacing. This may be elementary, but is there a file that is already out there that is made for surfacing the wasteboard or should I just make one?

Thank you all for your help!!

I load up a drawing of a rectangle into Estlcam and pocket cut it with the 1" bit defined. Seems to work for me.