Mark II

@kd2018 Hey, forgive me for being a total newbie on plasma, who is perhaps either dense or sleepy from too much Thanksgiving turkey…

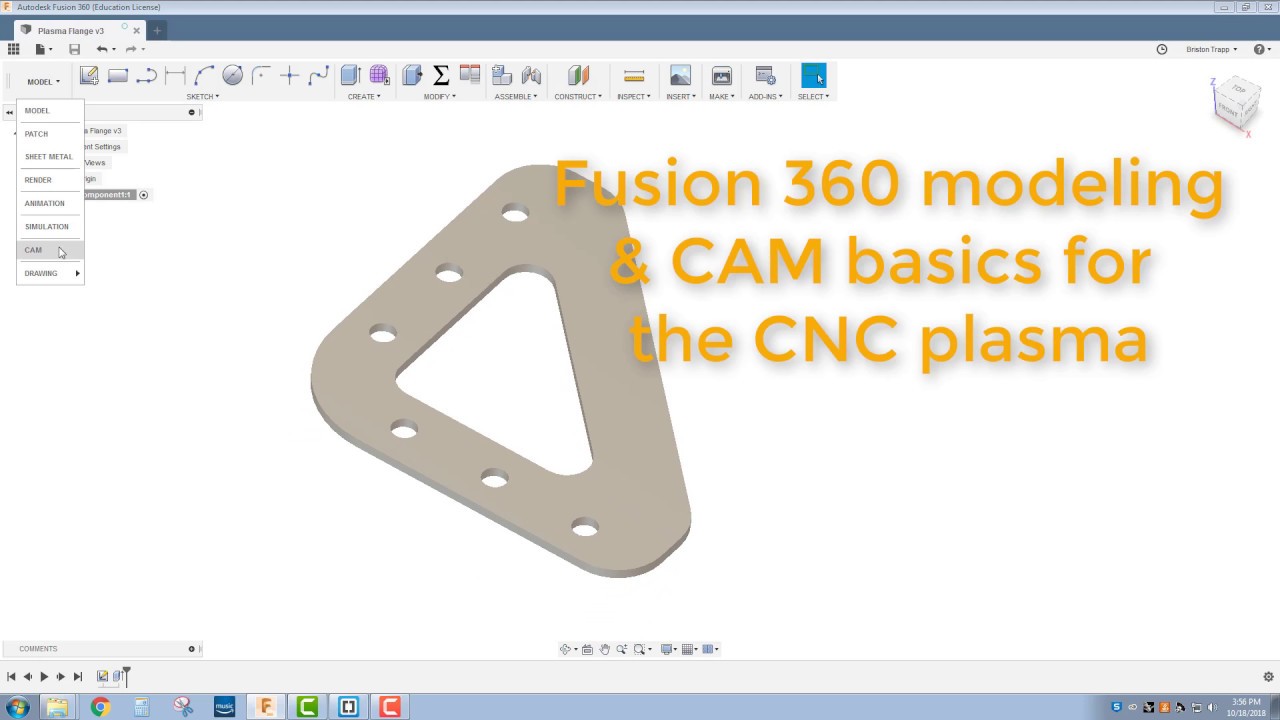

I’ve been watching videos about preparing designs for plasma cutting, including Clough42’s channel on YouTube showing how he does it in Fusion 360, and the tools in that are impressive. It takes into account the radius of planned bends based on thickness of the sheet metal, etc.

I’m trying to get my head wrapped around post processors and how I might be able to design in Fusion 360 and output for the LinuxCNC rig I’m trying to build. I am still deep in the effort to get it all wired and have not gotten to how to make a connection between design software and LinuxCNC.

I found this page showing a list of post processors to choose from for Fusion 360. Post Library for Autodesk Fusion 360 | Autodesk Fusion 360?

Is there anything in that list to choose? If not, any advise on how to go about things? Sorry to be so clueless.

Maybe I am overthinking it. Maybe do the design work in fusion 360, take advantage of the cool features (eg. accounting for radius of the bends etc.), but then simply don’t output my G code from there. Just bring the design over to LinuxCNC and ou put it from there. Does that sound more like it?

Over thinking it.

Same as always. Use CAD to design your part, in this case if you plan on attempting bends then yes you will need to design with appropriate radii and then flatten the pattern.

Export the DXF.

Open with ESTLCAM or sheetcam (specialty), add your lead ins (the only thing different from regular milling). Don’t forget the start Gcode you need for your plasmac stuff.

Export the Gcode.

Open with plasmac, and cut.

Make sure your material is selected and tuned.

So that is production settings. When you first power up and run basic movement tests, first real cuts should be designed from the built in basic shape stuff built into plasmac, with lead ins and everything. So basically don’t worry about designs until you verify your machine and wiring, there is a lot. I spent the better part of a whole day reconfirming all my stuff before making new cuts and testing feeds and speeds the rest of the day.

Regarding doing the CAM in Fusion 360 instead of ESTLcam or Sheetcam, this video is easy to follow and very enlightening.

Doing CAM in Free fusion is not recommended. You will not get different cut and travel speeds. Not sure if that effects XY and Z differences, either. Plus I just find it overcomplicated for a 2D part.

Got it! Thanks.

Thank you SO much for your awesome details and help!!! Such a great thing.

Quick question: In the graphic, for power for the steppers, you have the black “live” wire going into the stepper where its own label says “GND” — does that mean ground, and if so, is that a mistake in the diagram or is the live (+) wire really supposed to connect there?

UPDATE: answering my own question here: I was mistakenly thinking that black was still representing the positive side after the power supplies as it was before them. The switch from AC to DC was accompanied by a color switch on what black represented. At first I was not catching that.

UPDATE: I’m confused over which (red or black) is live line and which is neutral.

Can you clarify that for me? When I googled, black was said to be primary for live, and red was said to be a secondary color for live, so really either color could be it. I know I’m a little tired, but I’m struggling to figure it out. Thanks for any help!

After the power supplies you have DC power so a line difference of 24v, negative and positive. Wired just as it shows (or how you defined the pins on the pnfconfig).

Got it. My confusion was because black was positive (+) before the power supplies, so I started off thinking it was positive after the power supplies. However, after studying the diagram, I realized it switched black from being (+) before the power supplies to (-) after. That “switch” threw me. Thanks for confirming that after the power supplies, black is negative.

I think I am back on track now!

AC is neither and both, all has to do with which wire is where in your fuse box.

Got it.

I guess I have a ways to go to understand this. Before I was just going by the fact the power supply has V+ and V- outputs, and I was struggling to know which line on the diagram corresponded to which.

Does this (that AC is neither and both) mean it would not matter, and I could plug either line into V+ or V- and it would still work either way?

Correct. As long as you get the ground right. There is a safer way though, In the US black is +. (Future person reading this - It is different in many other countries, so if you are not in the US look it up!).

I am not the right one to be giving advice, though. I got scolded here for years about how I wired AC mains. There is a correct way, but both work. (if you look into it it has to do with where the switch is and how much of the PS gets energized when it is off on a poorly designed power supply. Good PS’s will be fine either way).

AC and DC are different.

It’s best to get out of the habit of thinking of AC as having a + and -. It will only lead to confusion in the future.

US AC (should be):

Black is live/line/load

white is neutral

green is ground

If you’re installing a switch, you should switch at least the black. But I think that’s based more on local code requirements. Not sure if any codes out there require switching both black and white. I know most of the lights in my house only have the black going through the switch. The white lines are all tied together inside the box.

DC (typically based on what I was taught):

Red is +

Black is -

Green is ground

Any other color is signal

I really try not to deviate from the above in my projects, but I have been known to use something other than Red for + if I had run out.

More theory: AC is alternating current. The voltage switches from 120V positive to 120V negative. That makes the current “push” and “pull”. The black wire spends as much time being a positive voltage as a negative. Don’t lick it.

The current has to go somewhere (and come from somewhere, because AC). The electrons that go in must come out. The neutral line is set up to be that sink. When the circuit is active, there will be current flowing through the neutral wire, and it will have some voltage (the amount of voltage varies, but since houses have long runs off wire, it won’t be zero). You still do not want to touch the neutral wire. It still contains significant AC current. Don’t lick this either.

The ground is designed to not typically move current. But it is built big enough to handle current in case it has to (it is the same thickness as the neutral and line). If the line or neutral wire ever got loose and touched the case of your refrigerator, the next time you touched the refrigerator, you would be in for a shock. So we always wire the case to ground. If that line wire touches the case, it will short to ground, throw the breaker, and you get spoiled food instead of electrocuted. The other reason for a separate ground is to have a reference voltage. The neutral makes a bad reference because it has AC current flowing on it.

Basically, treat the line and the neutral as though they are capable of hurting you and your electronics. The ground is your safety net. Switch the line, because neutral and ground alone aren’t capable of doing anything.

Part of the reason it is different than our DC electronics is because it is AC. But part of the reason it is different is because our AC circuits are capable of sending 20A over 200ft. Treating the neutral as negative in those cases doesn’t work.

240VAC has a lot of the same principles, but it has a second line, out of phase of the first. So the difference between line 1 and line 2 is 240V, then -240V. Moar power! Now you have two line wires. The current generally flows only on those, not much goes through neutral anymore. Sometimes the neutral gets dropped completely from circuits.

The electrical code is built from a bunch of lessons learned. Those lessons were people that died (and in the US, it has to be a lot of people that died) or property that was destroyed. They may not all be gold, but when you think you know better, you usually don’t. Hiring a good electrician is hiring someone that knows the details and corner cases better than you. You need to decide for yourself what level of risk you are willing to accept, and what the risk is worth to you.

So, is it safe to lick my refrigerator as long as the food isn’t spoiling?

Yes.