Hi guys, I need your support because today I’m getting mad.

I’m trying to enable the spindle ON/OFF trough M3-M5 GCodes on my SKR 1.3 Board and a iot relay board.

I have configured marlin 2.0.3 in order to enable the function:

#define SPINDLE_FEATURE

and disabling the other features:

#define SPINDLE_LASER_PWM false -> to send target speed reference

#define SPINDLE_INVERT_DIR false -> to send speed inversion

then I have mapped the output pin:

#ifndef SPINDLE_LASER_ENA_PIN

#define SPINDLE_LASER_ENA_PIN P2_00 -> SKR 1.3 servo output

#endif

with this modification the servo pin is 0 V or 3.3 V following coherently M3 and M5 commands.

the next step was connecting the relay:

wired:

Vcc to 5V (servo connector SKR 1.3)

Gnd to Gnd (servo connector SKR 1.3)

In1 to P2_00 (servo connector SKR 1.3)

swiched ON -> relay always active, no effect from M3-M5 commands

Then I connected the same relay board to an Arduino UNO, tested it with the Blink.ino sketch and I verified the correct behavior of the relay board that switches ON when In1 is connected to GND and OFF on other levels.

At this point I imagined that the SKR1.3 pin is not able to drive to Gnd the servo output and I found this resource:

https://electronics.stackexchange.com/questions/245976/control-5v-relay-through-3-3v-gpio-using-npn-transistor

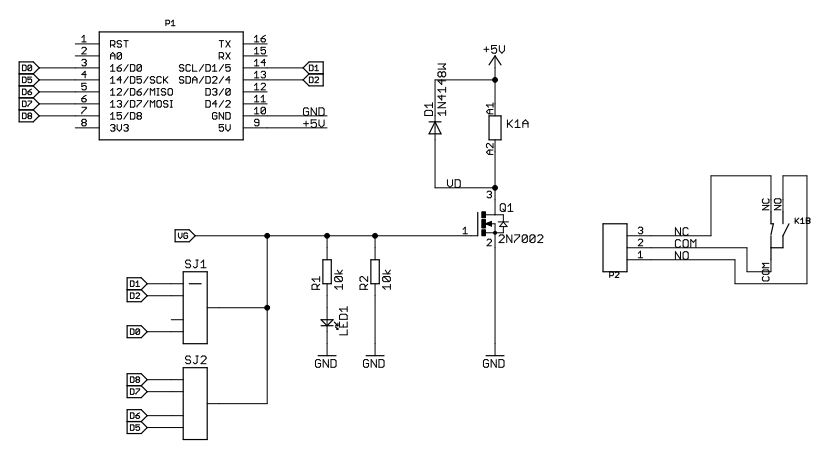

found in my lab some components and I built this circuit:

This circuit inverts the command logic so I inverted command logic in the fw by #define SPINDLE_LASER_ACTIVE_HIGH true.

Tested again and everything seems to work:

M3 Command

M5 Command

But… when switch on the board supply for about 10 second the relay is switched ON

Start after SKR1.3 supply

I have verified that during this “BOOT” time the servo output is driven at 1.22 V causing the spurious relay activation.

That’s all, now I’m really stuck with my mechanical engineer background I don’t know how to proceed to remove this spurious relay activation at startup… maybe I have only bought the wrong relay board…

Thank you for your support

Gabriele