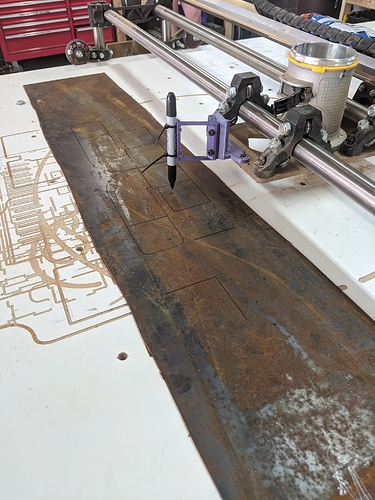

Who says you need a CNC plasma cutter when you have a lowrider and a Eastwood metal cutting jigsaw to make metal parts?

I’d love to have a CNC plasma but I don’t so I made do with using the lowrider as a pen plotter to mark the metal.

I designed the parts in fusion360 sheet metal tool.

Lesson learned here is don’t use a black marker. I knew better but wasn’t thinking. The marks became very difficult to follow once I started using oil to cut. That was the main cause of all the issues with this project.

Then after cutting it out with the AMAZING Eastwood metal cutting jigsaw and drilling out the holes with my less than amazing Skil drill press and step drills I bent the metal with 3d printed press brake to get the radius I wanted on the bend. At this point I wish I had a shop press. The press brake was printed at 75% infill and 8 walls. It barely scratched it. I feel like I’d be able to get a load more bends out of it. It has magnets epoxy into it to hold it to the vise

I then threw them in the sandblaster cabinet, deburred, and a couple coats of hammered metal Rust-Oleum paint, and clear coat.

Finished product. I didn’t get a pic of them on the bed but they look great. Take my word for it.