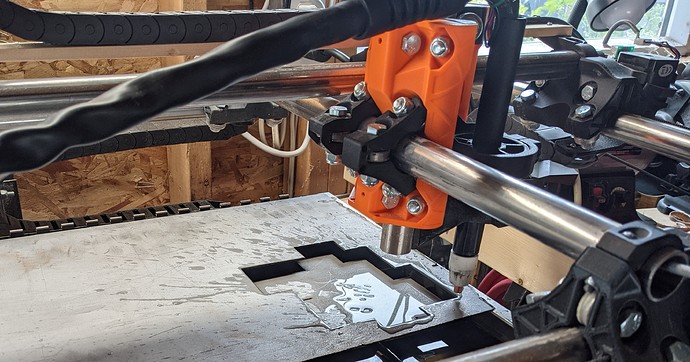

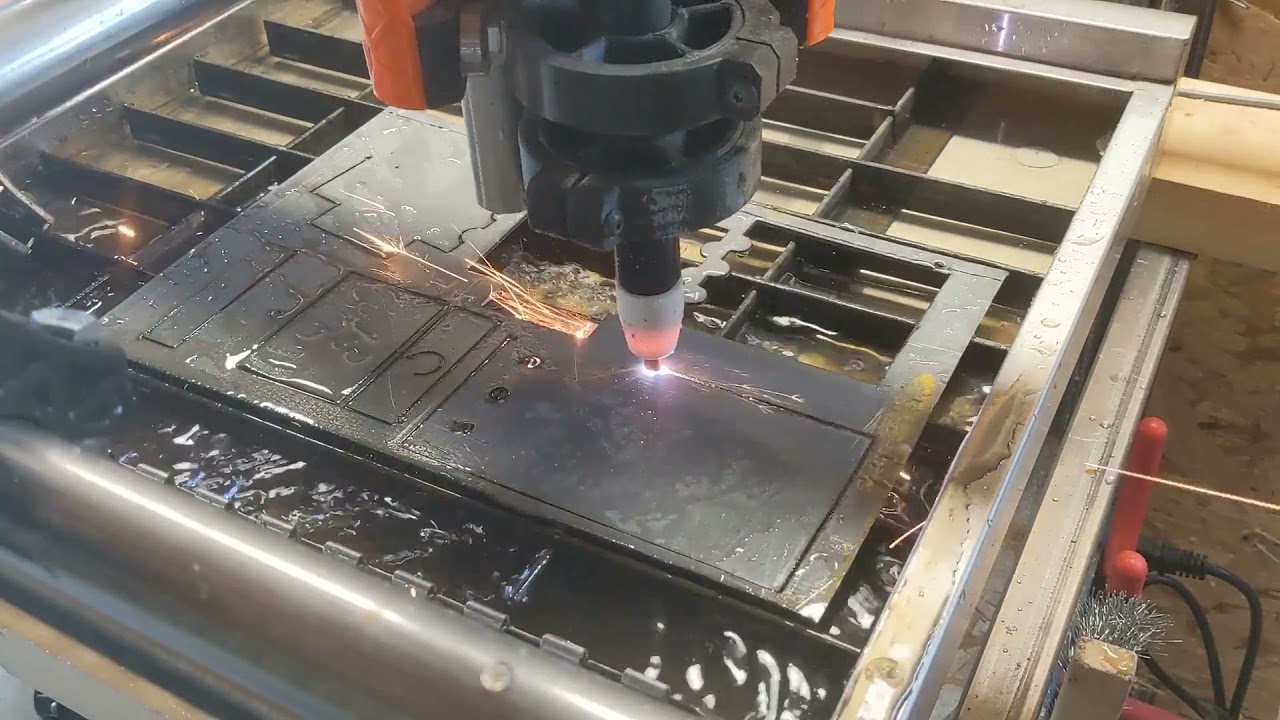

Hi everyone, like a lot of folks I thought a plasma cutter might be fun. But first things first let’s see some hot plasma and sparks:

My initial motivation was that sheet metal parts are “quick” and “easy”. Also, a cheap plasma cutter is like 250$CAD. If the EMI blows everything up, at least I’ll still have a plasma cutter. This was enough reasoning to begin 4 months of anguish.

I think most people are aware that there’s a lot of EMI with a plasma cutter. What isn’t explained is that EMI is a problem that is very difficult to track down and that you will go paranoid and mad trying to reduce it. I kept a log of all the cut I tried and it is in the 40s of attempts before I got anything to cut.

What did eventually result in cuts working was:

Physical Shielding:

- Shielded cable for all steppers

- Star connected grounds

- Shielded control box with shielded internal boxes for the arduino (grbl) and rpi.

- Double shielded USB cable between rpi and arduino

- Ferrites on anything that looked suspiciously conductive.

- Ziptied the plasma and ground lines together to reduce antenna loop size

- Separate the plasma from the controller as much as possible. I’m doing plasma on the left, controller on the right.

Software (GRBL + cnc.js):

- Run the job with 0 z-offset.

- Get the metal relatively flat and then auto-level (great cncjs extension) to get the torch snug to the surface.

- Added a 250ms delay after the M03 (torch trigger) command

What I considered doing but luckily it started working before I had to :

- Use a completely different (ethernet/etherCAT) controller

- Organize the cables in the control box to separate power and signal, 90 degree crossings, maximize separation etc.

- Buy a plasma torch that definitely is blowback

Some unanswered questions:

- What type of plasma torch do I have? I really do not know. It is certainly a cheap Chinese import plasma by the name: Reboot RBC-4500 aka CUT45. It claims to be a “touchless start”, there is no external wire I’ve seen on HF systems. If you look into the air tube there is a little bit of copper so that’s definitely used for some sort of starting arc. Hypertherm says they invented blowback by using a moving electrode. There appear to be no spring elements in my torch but I have no real clue. Is it a blowback in disguise? Couldn’t say.

Hopefully this inspires some more people do mostly plasma CNC setups. Plasma is fun and cool!

Just some general tips:

- Do not plug in your plasma machine until you are absolutely ready to hit start and run the job. There is a lot of water and electricity going on and you are made of water.

- I redid all my connectors while I was adding the shielded wires. I think as long as you’re careful with the crimps dupont connectors are fine but I did a bad job with the crimping and replaced everything with JST-SM or XH and haven’t had connector trouble for a while. For tiny wires under 16ish gauge I like to fully fold the conductor under the insulator now.