Sounds good… thanks for the details. Looking forward to trying it out.

I should have my Neje laser tomorrow - Curious to know what controller you have yours wired too. I currently have a SainSmart 5.5w laser hooked up to my OB BlackBox controller. I am thinking I wire up the Neje the same way but will have to see. I have Vectric VcarvePro with the laser add-on so not sure if I should stick with that or invest the money and go to lightburn. I am guessing Lightburn would be the better application but I have not looked into given my VcarvePro worked for the little laser engraving I have done with the SainSmart - With the Neje I am hoping to cut lite ply 3mm-6mm.

I really like lightburn and feel the cost is well worth it for the laser.

I’ve been trying to evaluate LightBurn. I’ve started an evaluation twice, and then something comes up and it epires before I get to actually try it, so I’ve got all my laser Gcode generated by something else, except for a simple nametag burn.

I’m a Lightburn fan (and not affiliated in any way)… and it’s worth every penny IMO. My daughter loves it as well. I’ve got both diode and CO2 lasers and can generate cutfiles – both gcode and DSP – with it. I then use V1Pi/CNC.js on Pi-3B’s to send the cutfiles to any of my several machines. I’ve got Lightburn running on two Chromebooks and a Linux Mint laptop.

We also have two friends who sprang for Neje Master 2S Plus laser engravers for Christmas this past year – on our recommendation and promises of help to get them going – and we set them up with trial Lightburn on Windows laptops and got direct LB-control of their machines. Pretty neat! I’ve also discovered since that my Chromebooks with Lightburn can do this also… it’s just a serial/USB connection.

I’ve also found the Lightburn staff (it’s a very small outfit) to be very friendly and helpful. The 30-day trial is pretty generous… but if something comes up – and you ask nicely – they’ll generally extend it a bit to help you get your machine going. They also advertise installation on TWO computers but will happily extend that to THREE machines — again, when asked nicely. And the LB forum, like this one, is generally well-behaved and helpful… and Oz (the LB owner) and other LB staff actively participate to provide in-depth help and address issues.

My $0.02.

– David

I love LightBurn. I don’t use it as a g-code sender, but just to generate g-code. I run headless and have my g-code generated as coordinates relative to the stock, so my workflow is very similar to using the router. There are some benefits to using it to directly send/control laser jobs.

I cut a lot of 5.2mm plywood for Christmas gifts. Cutting was slowish, but it got the job done.

The Neje 4–wire cable is easily managed… the 4th wire (green) is a temperature control signal that can be generally ignored and/or clipped. The other 3 wires then are the common +12V/GND/PWM wires found in other 3–wire laser connections. They actually provide a little interface board that allows a variety of ways to connect up your laser control and power…

Pretty convenient, if you need it.

– David

thanks for the information… One question on the Lightburn… does that work both as CAD/CAM ?

My workflow for my current set up is to do design and post processing in Vectric VcarvePro with the laser module and then I export the gcode. My main PC is in my house. Upload the gcode to my google drive and then in my shop pull it down from google drive and run it on my CNC PC which is running OpenBuilds control.

Just trying to figure out if I go with Lightburn if I need to copies or just one, etc.

I’ve used it both ways, when I’m testing out projects I’ll run it directly from lightburn with a USB connected to my lowrider. Once I’ve got it sorted out and it’s a project that I’ll run repeatedly, I’ll generate gcode and throw it on an SD card to run.

LightBurn will generate a g-code file, or it can be used as a g-code sender. I run headless and use it to generate g-code. Using it as a g-code sender gives you some benefits. For example, if you pull your stock off the machine and find that it did not cut through in places, LightBurn has functionality that allows you to replace and align the stock for another pass. It can also outline the area where it thinks your stock should be so you can make sure you have things setup correctly before you start cutting or engraving.

The LightBurn license allows you to have copies on two machines.

Robert and Robert told you true. LightBurn can do direct machine control without generating a gcode file… or you can create a gcode file to use with another sender and/or SD card. I particularly like @Basstone18’s method of testing with direct control and then commit the gcode to SD.

The direct control thing is really neat, BUT… after a run I have no way of telling what settings were actually used for that burn. And, of course, I’d never think of scratching the settings on the back of the piece. And, at some point down the road, I’ll guarantee I’ll go back into the LB file and jack with some settings… and all is forever lost.

When I create a gcode file, however, I try to embed the major settings in the filename; i.e.

“image_thing-e1200_85_339-jarvis-1xp120_100.gc”

That tells me that “image thing” is engraved at 1200 mm/min, 85% power, and 339 DPI with jarvis dither and a 1-pass profile cut at 120 mm/min and 100% power. As long as I can associate the job with a particular gcode file, I can know the settings I used. But, of course, I can still mess it up… I’m the “king” of disorganization

BTW while they advertise their license allows LB on TWO machines… they almost always will allow THREE, if you’ll ask them nicely. I’ve got LB on my daughter’s Chromebook, my Chromebook, and a Linux Mint laptop… three machines. No begging, no hassle… they were happy to do it.

– David

Thanks for the details… the laser arrived today but the one item that has me stumped is the pcb that has the digital read out. I was hoping the wiring set up would be close to my Sainsmart 5.5w laser given I have all of the wiring in my cable chains already. I have the DC barrel jack, the three pin jack and the two pin jack but looking at the pin out between Sainsmart and this one they are not the same pattern. If I am not mistaken there needs to be a shared ground. I was looking at the BlackBox manual and I am guessing this is considered a three wire configuration. All that said, still not sure about that other PCB that was in the box.

I think the other pcb with the digital readout is just a manual control to show/control the power level. I did not utilize this board in my setup.

Thanks for clearing that up for me.

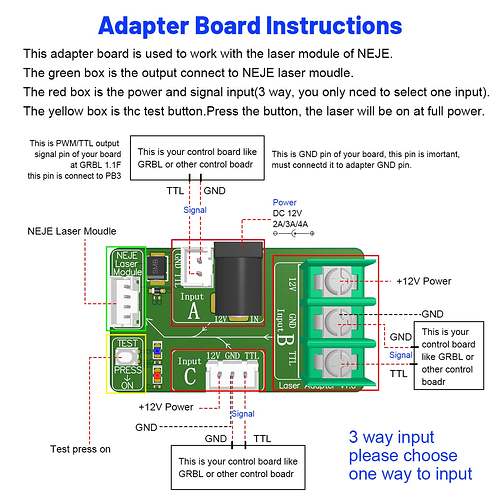

On the little adapter board photo (the one without the digital readout) I show a few posts back – if you choose to use it – it gives you 3 different ways to connect your Neje laser module to your PWM controller and laser power.

-

Notice the screw terminals at one end. They show TWO wires to the center GND terminal where the GND “sharing” would occur if wired discreetly, when using separate power supplies for your controller board and laser.

-

A second connection scheme using the 2-wire connector and the barrel-jack… it connects the GND in the 2-wire PWM connection from your controller and the barrel-jack GND from the laser power supply with the adapter board’s plane/trace wiring.

-

The 3-wire connector might be used if you’re using a single power supply to power both your controller and the laser. It implies the GND-sharing is taking place in your controller and all the laser’s required power is coming through those tiny pins in the 3-wire connector. This is probably “sketchy” at best and IMO not the best connection scheme to use.

That little board with the digital readout is SUPER HANDY for testing your Neje laser before connecting it to your machine. Just plug in +12V power brick and the laser module and use the little board’s PWM circuitry to turn on and test the laser to find where the factory focus is set. You can then cut a gauge block to quickly set focus distance to the material surface… like this

– David

Coincidentally the power jack and the two pin connect that I had wired for the Sainsmart turned out to be plug and play for the Neje. So I have it up and running - tried it on 6mm ply with a simple star that is about 25mm x 25mm - I ran at 100% and 7mm/sec with no air and after five passed never cut through.

I put your 3d printed nozzle on and just ran it once with no air to see what it would do and the tip basically melted. I printed it in PLA and understand that it should not be ran this way without air.

I am guessing I don’t have the correct focus even for five passes no air or the ply I have just will not work. The ply is craft plywood from like Menards or Hobby Lobby, etc.

The little pamphlet that came with it said to set it at 25mm from the bottom of the lens cover to the surface which I did. I had the ply sitting off the spoil board between two boards so there was a gap but it never cut through.

The only air I have it an aquarium pump so will given that a try until the bigger pump gets to me.

Which model did you get? The one I got is a fixed focus and I set it at about 18mm height from the bottom of the aluminum body.

I got the A40640 model. I have read that some plys cut better than others… something to do with the layers and glue… but I don’t know much about it at all.

Air makes a big difference. You should be able to easily cut 3mm ply one pass at 80% and 150mm/min, which is 2.5 mm/sec.

I was working with 6mm… cannot find my 3mm ply right now… normally I’d just be using the 3mm