2020 06 29

Hi!

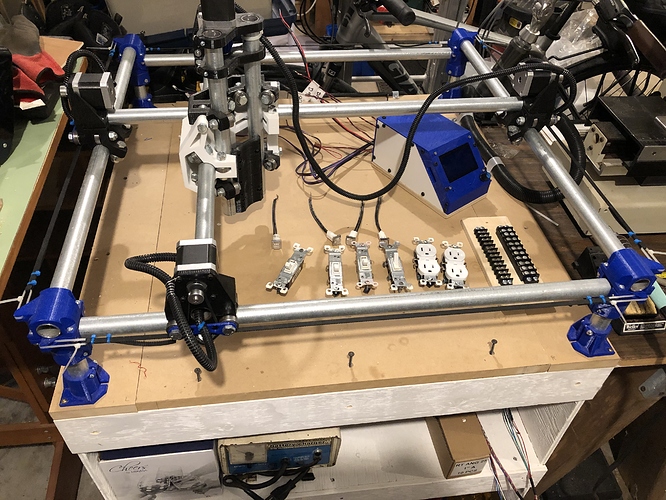

My MPCNC is finally coming to an operational state (I hope). I started building this machine over 2 years ago. I bought everything, put it mostly together, and then got side tracked and left the MPCNC alone for most of those two years.

I’m now retired and that and covid gave me incentive to get this machine working. There have been quite a few changes in my down time on this project.

The machine I’ve built is pretty standard. It’s roughly 30" square, uses the 1" conduit, has an Arduino Mega 2560 and RAMPS 1.4 board with 8825 drivers.

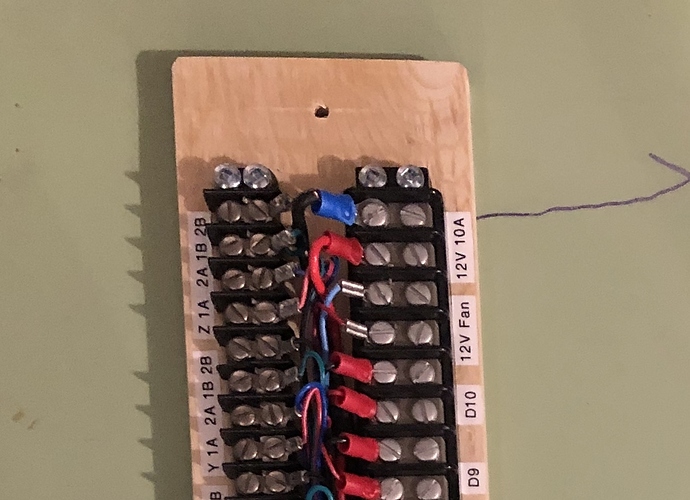

The steppers were a bit of a departure from the norm. They are 3V, 1.7A motors with 400 steps/rotation. I’ve wired X and Y motors in series and I run from an old ATX PC power supply at 12V, 10A.

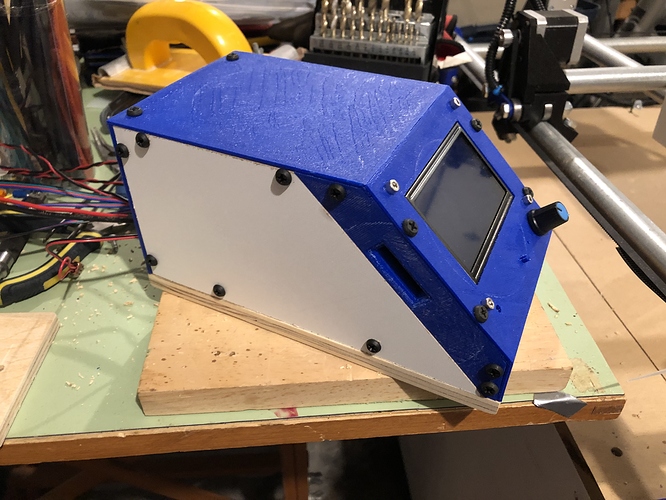

I designed and printed a box for the Arduino and RAMPS with the ST7920 (128x64) display.

The controller, power supply, and 110VAC wiring is not all tucked away yet, but otherwise the machine is done and I’ve begun testing.

The MPCNC seems to be fully functional, but I have some questions about:

- The feed rate settings for the horizontal and vertical axes

- The controller SD card shows folders, but not any files (I’ve tried .gcode)

- Whether or not the CAM software (whatever it turns out to be) will properly limit the Z feedrate

- The XY motions are only about 62.5% of the expected motion. My steps/mm must be wrong, but I am not sure why