I tried to find the post, but gave up. The forum sure is busy these days!

At any rate, you said something along those lines (if indeed it was you). Something about a machine being off by almost 10 percent on step/mm was a major problem, and that perhaps a percent at most might be expected.

The “standard” advice I’ve gotten (and unfortunately followed until early last week) was something like…

1)measure your filament through the extruder over 100mm, calculate the steps and update it.

2)print a single-wall cube with no top and measure the wall, adjust the flow rate until it matches the nozzle

3) print a cube and calculate the xy steps/mm.

I can see a few reasons why that’s not a great way to do it, now, but I never stopped to THINK about it until you mentioned a machine being in good repair. The first problem is that it’s really hard to measure EXACTLY how much filament goes through that extruder, especially to the precision that the stepper can execute. The second is that there is ALWAYS some measurement error, especially by a schmuck like me. After that, like you said…plastic is unpredictable and will blob, expand, shrink, etc.

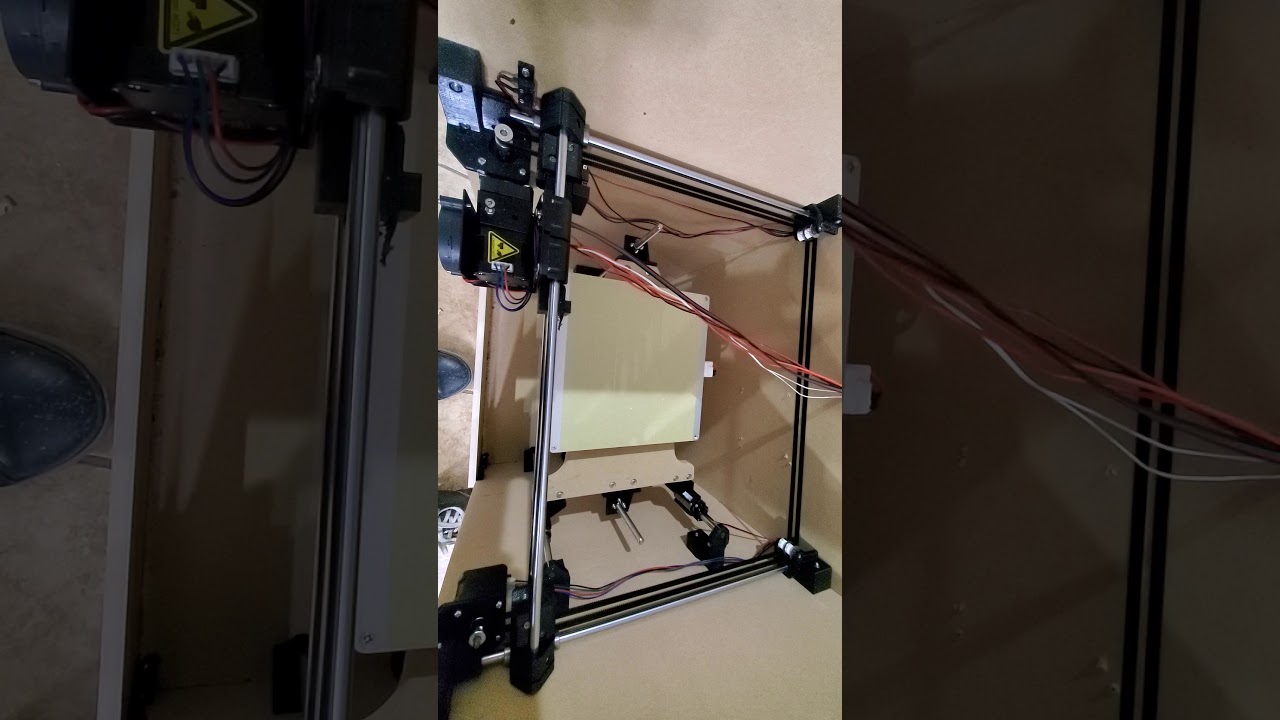

All the parts on my printer are commercial, and all the important characteristics are well-defined…angle/step, teeth/pulley, etc. If something isn’t moving the right amount, it likely needs a tuneup. So, I reset my software, broke out the dial indicator and did some measuring. Ended up tightening the belts a little more than I thought I should, but I got so close to the measurements I expected I felt comfortable that I just had some measuring errors and left the calculated numbers in it.

After that, the blobby/oozy part was all that I had left. That’s where I started scratching my head. I’m still not sure about the nozzle diameter influence, but I reasoned that the slicer must care more about the width of a line than the actual nozzle diameter. In Cura, there isn’t even a nozzle input anymore. So I measured a bit of plastic from the nozzle and used that instead. Then if the printer isn’t laying down the right dimensions, it’s GOT to be because it’s squirting out too much or too little plastic.

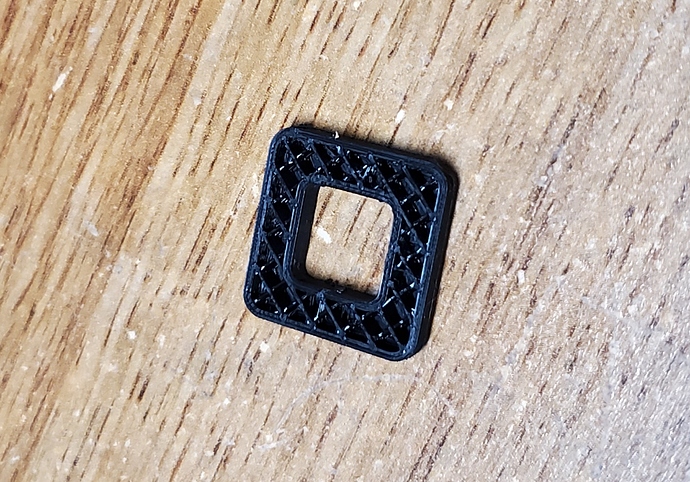

I made a quick shape (picture below) thinking that overextrusion would make the outer measurement too big, and the inner too small…by the same amount, and vice versa for under extrusion. Lucky me, that’s exactly how it turned out. I was going to use a circle, but remembered the whole deal with polygons and didn’t want the possible error. I was just going to plug and pray with the flow rate, but since my algebra needed a workout I drew a picture, made a variable, and boom half the error + the extrusion width all divided by the extrusion width is the percent of over extrusion. The reciprocal is probably closer to the correct flow rate. Plugged it in, bang-stupid close to actual dimensions.

Anywho, here is a picture of the shape I used. The inside should measure 10, the outside 20. If they aren’t off by the same amount, probably the steps aren’t right. If they are, any difference is in the extrusion. The corners are rounded because @vicious1 pointed out to me a little over a month ago that square corners ALWAYS blob (re the primo calibration test), the bottom is chamfered because elephant foot, and I printed without a top because speed/material.

Of course, as is the way, I found this on thingiverse over the weekend. The inside shape and outside shape are the same measurement, so it might be easier the think about, and the outsides of the arms are 20mm apart, so it does all the same stuff mine does, PLUS if you print two, you can try to fit them together for a test without measuring. Bonus, somebody made a calculator for it. Like, 4 years ago. Before I even thought about getting a printer and listening to bad advice about setting it up.

Anyway, that was the journey, and I can’t argue with the result. I’m the guy that brings something to measure pipe at the store because I can’t eyeball a 1.25 pipe from a 1.5 (had to fix a sink earlier tonight, lol). I mean, put them side by side and I know which one is bigger, but hand me one and ask which it is…better be printed somewhere. And I’m measuring a 4.3mm hole that’s exactly what I modeled within the error on my digital calipers…I’m a happy dude.