Starting my printing this weekend. Is PLA+ ok to make the parts with?

I built mine with PLA+. I’m not quite sure what the difference is from ordinary PLA, but I think it’s pretty minor.

Just hearing it might be too soft? its weird, Ive never seen the diff, but thought id check

You might find that items like the Router/tool holder etc don’t like it if the actual motor/tool gets hot.

PLA suffers badly when things warm up.

I nearly always use PLA, but I did spend twice as long and print all mine in PETG and it’s far stronger.

Probably only one way to find out!

Might do first set in PLA and those which I see sit on the motor Ill swap to PETG.

If you’re building with the 660, the case doesn’t get hot at all. Pla stands up to the steppers with no issue, so it’s probably not worth worrying about. Of course, it’s a non issue for your drag knife

thanks man

Ryan’s recommendation is to use PLA. There are a lot of builds in PETG though. The common recommendation (thanks to Barry) is to use more perimeters when using PETG, because it is not as rigid as PLA.

yeah but is PLA different PLA+ in a negative way for this project.

I don’t think it is negative, except for the additional cost. The motor mounts and the spindle mounts are the only parts that would come close to needing some additional temperature performance.

I have also seen that these HTPLA or PLA+ Filaments need to be annealed at 200F to get higher performance, and I thought I remember seeing that regular PLA can also benefit from annealing. So I wonder how much difference there actually is. There is no free lunch, so I am skeptical. I have used some HTPLA from protopasta and some from matter hackers before they got weird. I like the feel of the stuff, and it seems plenty stiff to me. But that is the least scientific opinion possible

Also, the annealing process will change the dimensions of the parts. They tend to shrink in the XY directions and grow in the Z directions. Not a good result when fitting parts together for something like this.

PLA+ is different between manufacturers… it is PLA with additives. Most likely TPU to make it less brittle. Should be fine I think.

PLA is better than PETG since it’s more rigid. PLA is also more rigid than PC. Someone mentioned carbon fibre - nylon which sounds interesting.

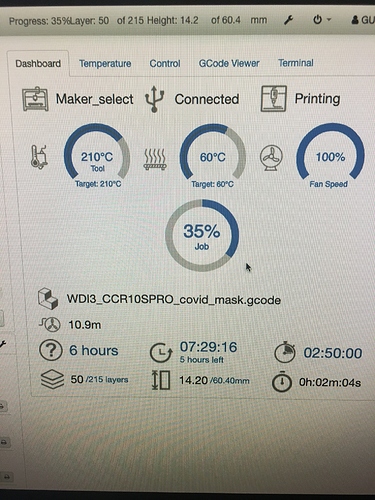

I could never print PLA and get a good reliable part at 190C -200C. Just to give you an exemple, right now I’m printing masks for MGH in Boston, all PLA… one printer is going at 210C

and the other at 220C.

and if I don’t bring the Temp up this is what happens… the layers don’t stick!

that was printed at 210 on my crt10s-pro all metal hotend.

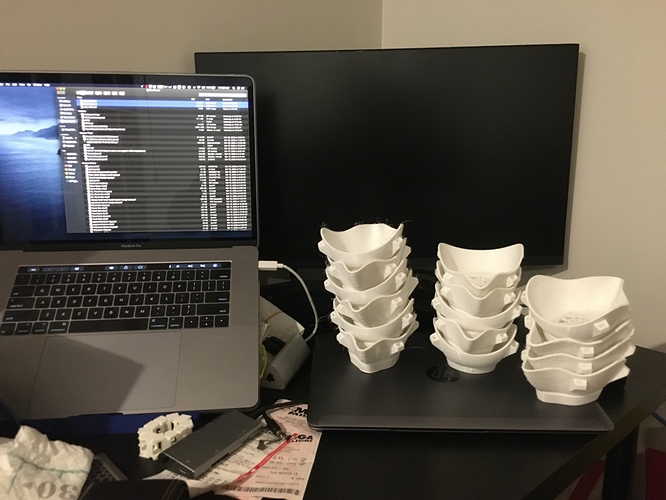

here are some of the masks that will be donated this sunday.

I’m hoping to have 30 done by then…

Gustavo

my PLA prints 205 like butter!

I think these cheap thermistors we use are generally pretty good at relative temperatures. But they are either misconfigured or just inaccurate at absolute temperatures. So if you print at 220C instead of 210C, I think that will be reliably about 10C hotter. But I don’t think it is really 220C. So I don’t worry about that as much as trying to calibrate it with each filament.

Interestingly, sugar will melt at about 190C, but not at 175C. I am having trouble thinking of a way to use that information to calibrate the hot end though, because melted sugar is a mess.

Maybe you can check/validate that with an IR thermometer?

I don’t have one and use a sock at my hotend.

I have always wanted to make a test pattern generator for dialing in settings. There are a million test objects for evaluating a single set of settings, but it seems to me it would be much more powerful to sweep a few settings within a single object and have the outcome tell you the best value directly. A few jobs, sweeping a couple parameters each, should get damn good with very little trial and error. TBH I am surprised nobody has done this yet.

But alas, it has not risen high enough in my list of projects.

They don’t do great with reflective surfaces. If you had some kind of temporary high temp black paint or tape it would work I think. Maybe just rigging something up so the nozzle was pressed against the metal end of regular oven or meat thermometer might work.

They do alright with the melted filament that gets all over the hotend though.

Mine seems to have a hard time with something as tiny as the nozzle and my block is chrome… maybe I’ll have to give it another try now I have one of those black e3d nozzles though.