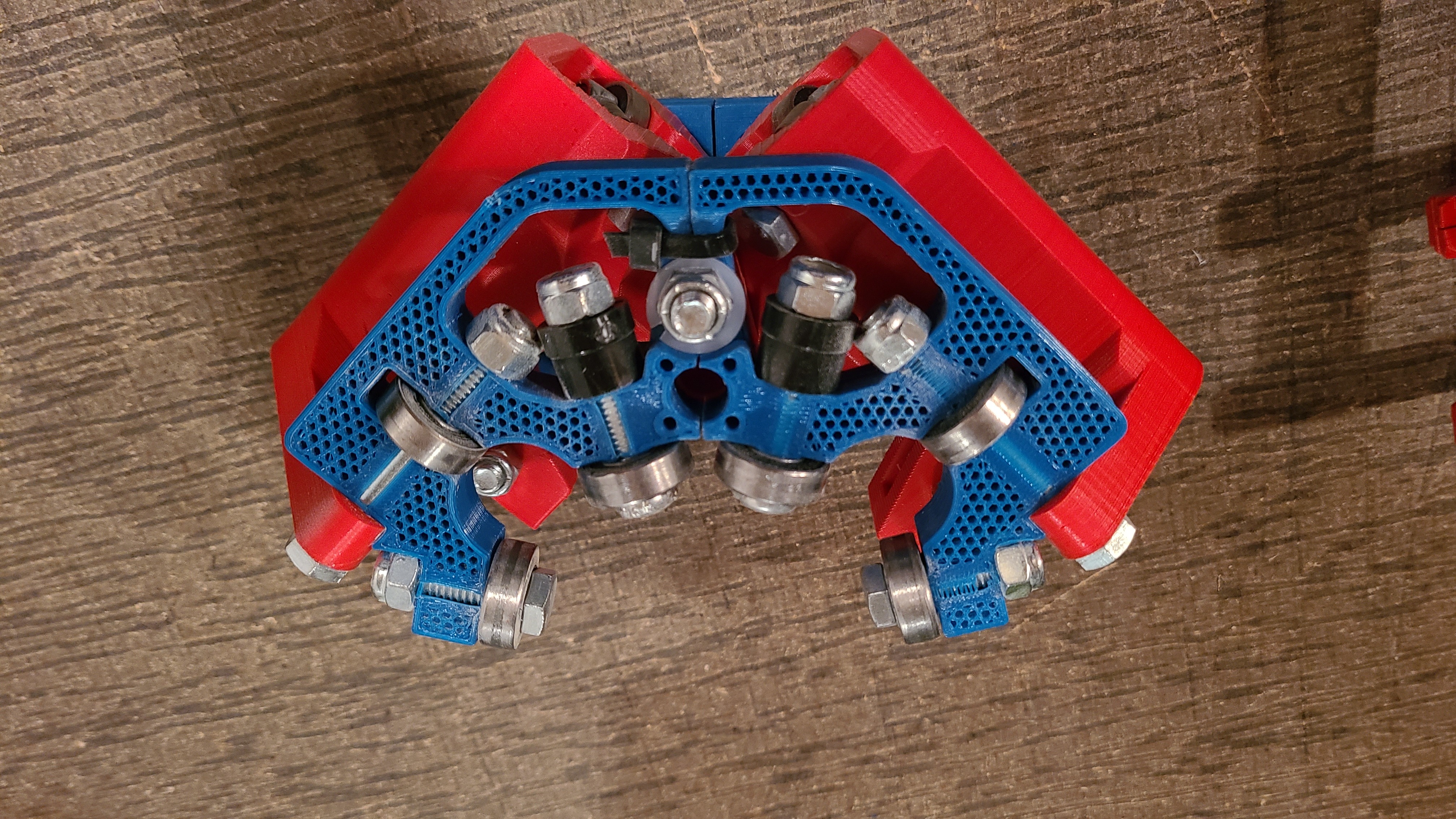

A picture is worth a 1000 words …one of these is not like the other.

I think my new drybox isn’t letting the filament pull smoothly which is causing z-banding.

A picture is worth a 1000 words …one of these is not like the other.

I think my new drybox isn’t letting the filament pull smoothly which is causing z-banding.

Well, the good thing is it will most likely still work fine.

If that were mine… Most of those 1000 words would be four letter, and yelled at high volume.

It does seem that all of the functionality of the part is there. I know for myself, I would probably keep it ass a backup, and print a new one anyway.

The banding would bug me some too. My old printer does that, it might be my print spool holder, which was pretty crude. I’ve been meaning to re-make it so that it’s smoother.

I wasn’t even thinking of trying to use, but you’re right, based on visual inspection all the important parts are there. How would I know this doesn’t work? I’m looking at the instructions and it doesn’t look like that area of the part connects to anything. Would it be structural weakness then?

The only issue I could see is that you would have problems squaring when using hard-stops or auto-squaring switches due to that truck not being the full length. Generally when I am squaring my machine I measure off the ends of the trucks to the ends of the corner mounts.

Now I’m not saying it’s going to work perfectly and I’m not trying to cause headaches for Ryan by recommending you use out-of-spec parts, but from my personal experience, these machines are pretty forgiving and can operate within tolerances with imperfect pieces. My first V1 machine I made was the Burley “C” version and my bottom XYZ plate was 75% as thick as it should’ve been due to a power failure during printing, as well as having to be printed in two pieces because my first printer couldn’t fit the whole part at once, without being split and nested on it’s small bed.

I didn’t seem to have any issues with it, but your mileage may vary.

i admire the intrepid “use it anyway warriors” for their ingenuity and hutzpah, i even wish* - sometimes (with my right brain) - that i could join in their ranks. but alas the left brain makes quickly with the dispatching of the long, long, laundry-list of concerns that crop up, while at the same time reassuring me how much better it would be if it were just a smidge closer to perfection… but that’s just me, i like how tim put it: your mileage may vary. best of luck!

*maybe then my machine would be together by now

I feel your pain. I swear that the trucks are haunted, I have had 3 attempts at printing mine. Power failures, filament out sensor failure and octoprint lockup, the closest I have come is 91%

Still trying tho.

An appropriately sized UPS would weather the blips. It may not last through full power loss more than a few minutes, but a surge would be no problem.

I am planning to print a lithophane of the moon…its close to 20 hours for each half. I will not start it until I get a UPS.

Some printers have firmware that can resume after a power failure. I’ve used that feature twice, so far it’s worked both times.

What is this firmware please??

It’s printer dependent. Need to check with your printer manufacturer. I’m running klipper on my printer.

I agree with @barry99705 in that is it very dependent on the printer. I have an Ender 3 and 3Max, one has a custom FW that I did, and one I am running TH3D’s Unified FW. I have never had to use it, but have read about many who have had success with it.

@nstiesi I just finished a 4 day print…had no issues, but there was a bit of a pucker factor every day when I woke up and then got home form work. Unless you have known power issues, I would say give it a go.

Filament runout is also a nice thing to have on a printer.