Does anyone know of any DIY CNC carving machines with a rotating jig that would allow full 3d parts or a 4 or five axis machine?

There are 5-axis milling machines. The smallest/cheapest production machine I’m aware of is the PocketNC with a base price of $6,000, and a pretty small milling area. On the DIY spectrum, I’ve seen jigs that allow a person to rotate a piece of work using a standard 2.5D machine. Take a look at this YouTube channel. He demonstrates a 3-sided and a 4-sided jig to create some impressive carvings using a Shapeoko.

The Snapmaker2 claims 4 axis milling with a rotary modual add on… base machine is 1800 and rotary module is another 600. 12x12x12" work area.

There are also at least one good thread on here about adding a 4th axis to the mpcnc. But working with 4 axis gets expensive as I have yet to find any free/cheap cam that will do the tool paths.

I just saw a 4 axis DIY machine on cnczone.com forums. Much pricier than a Primo, but I did think that it wouldn’t take much to adapt that 4th axis stepper to use a NEMA 17 instead, and place it in a Primo’s build envelope. It would need either a 6 driver board, or to use the series wiring variant. The problem with the series wiring variant is that for the 4th axis, you want something where you can reliably place the CNC over the center of rotation, and it would be best to have limit switches do that function for maximum repeatabilty. The X or Y axis must be consistently parallel to the axis of rotation in order for this to work well.

There was a fun thread where Leo69 worked out how to get a 2 axis + rotation axis. He basically plugged the chuck motor into Y. It was able to do things like cut out egg shapes. I think it could approximate pockets in a rectangular object, but not well.

Real 4 axis requires tricks with the firmware, and then software to create the CAM. Maybe you could get away with Marlin thinking the rotation axis was the extruder and you could turn on cold extrusion. If you just wanted to cut 4 sides of something, you could just do gcode, and then send a rotate 90 command, and then cut the next.

Our machines aren’t very symmetrical though. We have 24" long X and Y but 3" Z, and most of that is for meneuvering the bit around. Cutting 4 sides of a 3"x3"x3" cube is possible. But there will be a real uphill battle with anything over that.

I am coming from the SainSmart 3018-Pro to a LowRider2.

The 3018 communities use a 4th axis rotary custom build using a stepper motor, 3 jaw chuck from harbor Freight and a 3d printed spindle end or purchased spindle.

As long as the board can handle the input/output and the software you have can handle it, then you are set to go.

There are even gear reduced 4th axis assemblies available through AliExpress and others.

I am using DeskProto Hobby license with can do all four axis.

I also have most of the parts to make the rotary (was going to di it on SainSmart)

The LR2 build I am doing will have a mildly custom table including a section that has a rotary added, eventually.

You could always mount the rotary module on an adjustable drop table.

It’s probably not what you’re after, but the EggBot was pretty famous in the early days of hobby CNC

I have too many projects already that aren’t close to finished - but oh my gosh - I want to make an eggbot before easter!!

Are you btw familiar with the eggbot? How easy is it to make it by yourself? We already have a cnc, and tons of arduinos of different sizes…

I’ve not built one, but they look pretty easy compared to building an MPCNC - especially if you’ve got an MPCNC to help cut a frame. Although I think I’ve seen them made from Lego.

The egg bot was one of Bruce Shapiro’s project. Bruce is the CEO and founder of sisyphus. Wouldn’t it be great if someone put a sandify pattern into an egg bot?

Thanks for everyones input. Plenty to explore there.

MP

I’ve made one. It was pretty straightforward, and the parts didn’t take too long to print. Definitely doable by Easter, and really fun to play with!

Which type did you go for? I see that there are quite a few different approaches out there.

I think it was the Sphere-o-bot by jjrobots.com. I bought their hardware kit and printed the frame, pen arm, etc. myself.

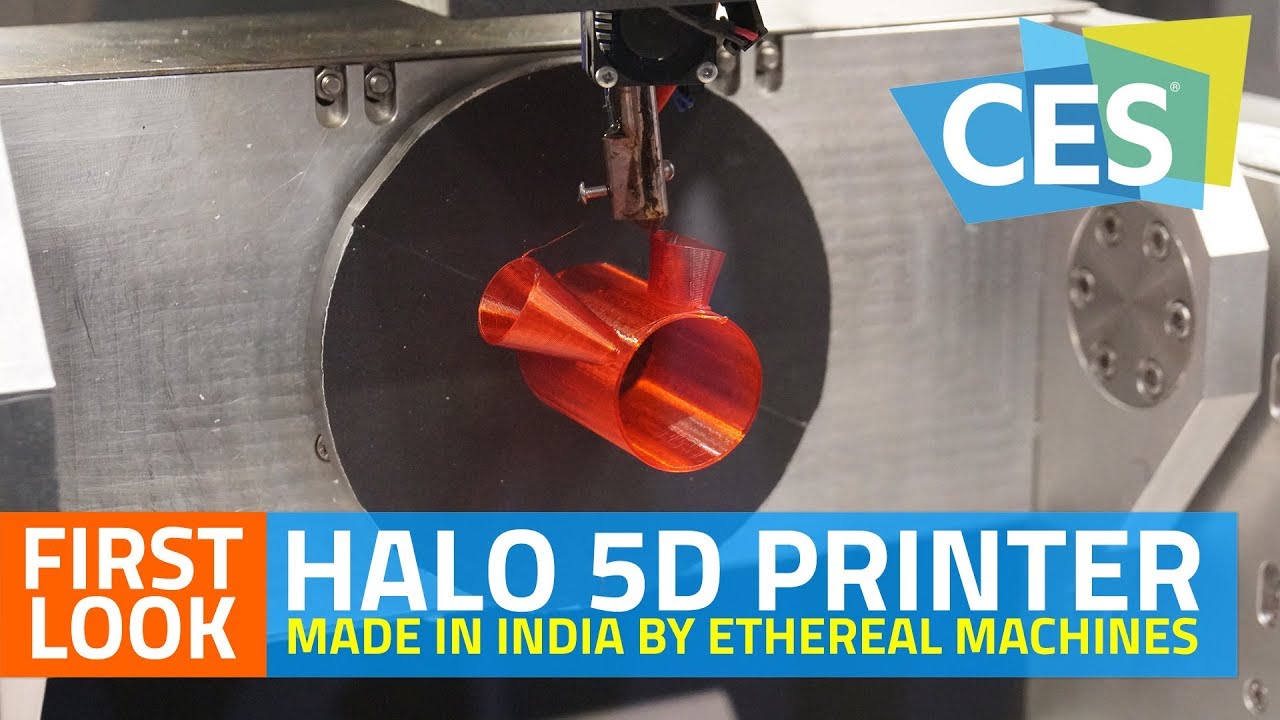

Neat stuff. Probably quite niche, as you’d have to have some structural/material/mechanical engineering to best determine the orientation of printing for each layer or facet. But it would allow for printing some interesting shapes with the layers oriented in more optimal directions. Although, I didn’t see it using more than two axis at once… It would be infinitely more interesting to see it actually manipulating it on all 5 axis at the same time while printing, creating non-planar layers. At best, it was creating curved layers on a cylinder.

Acchhtually- there are some doctorates that try to solve that issue with an ALGORITHM… 5D printing and algorithms, it sounds kinda gimmicky to me! But there might be something to it.

This earns a ![]() .

.

There are a few cases where it would be nice to be able to change the orientation of gravity while printing. It would certainly make a few things more possible. But I also think it will need to be nearly free (like part of a creality printer) before it will be of much interest. Mostly, I can make just one or two decisions on a part to make it print upright. If I had to spend $5k to get a printer that could print in 5D, it wouldn’t be worth it (probably).

I imagine that such a printer as in the vid hardly ever could be affordable for the hobbyist. But the idea of printing objects where the workplane at any time could be rotated in both directions is kinda enticing! The first layer would need some tough glue though…