I’m hoping that someone can rescue me from what is apparently my failing memory…

This relates to (non-dual endstop) Primo build that was completed nearly a year ago. It uses the SKR1.3 board, the TFT 35 display and TMC2008 stepper drivers. I used the V1 version of Marlin, and according to the downloaded file, it was “Marlin_V1CNC_Skr1p3_2209_2.0.6.1_505-src”, downloaded in September of 2020. I was able to get it running with few complications, and eventually printed out the crown and did a preliminary job to set up a spoilboard, that was flattened and had some holes cut for threaded inserts. I use ESTLCAM for all this and it worked. (This is actually the second MPCNC, the first one being a Burley, and the third one being an “in-progress” LR.)

After that preliminary work, I had to put the project aside for a while, so, it has not been touched since January 2021.

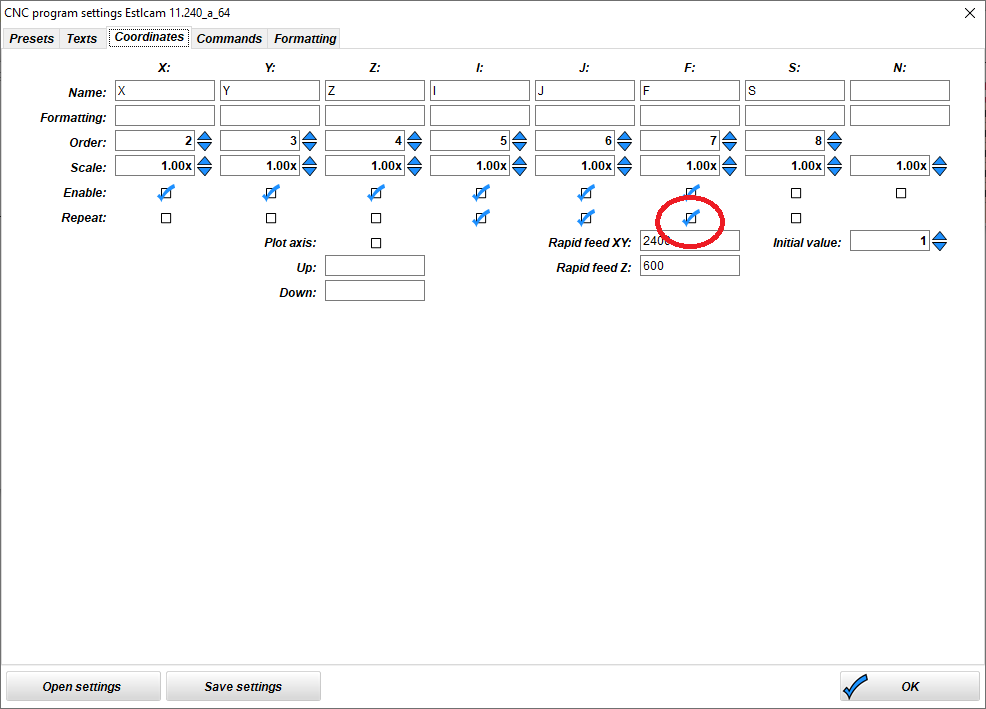

This week, I went to get it fired back up and work on a new project, and ran into a problem that I have a memory of from January, but cannot find any reference to a solution. The motion of the steppers when under gcode control is EXTREMELY slow. I mean, at least 10X slower than it should be. In fact, I tried to run a gcode file on the Primo after running the same file on the Burley, where it ran at normal speed. It would have taken hours to complete, instead of the 50 minutes on the burley.

It should be noted that this occurs ONLY when it’s under gcode control. Manually moving the motors results smooth movement at normal speeds, so the steps per mm must be OK. (As far as I can tell by inspection of the old PlatformIO file, it is just the default values.) And, since the same exact ESTLCAM-generated gcode file runs slow on the PRIMO and normal on the BURLEY, it doesn’t seem that this could be the issue.

I have a sort of vague memory that I briefly suffered from this same problem back in late 2020 when I was first getting it going, but it was obviously solved since I believe that both the crown and spoilboard were normal speed. However, I have been unable to find any reference to a solution.

I also have some vague idea that it MIGHT have something to do with the display, which of course can be in either Marlin or BigTree (Touchscreen) mode, but, I tried both and there was no change. (And, this doesn’t make sense to me anyway.)

Finally, I should add that the firmware has not been touched in any way since it was first functional back in January 2021, so, this is not a “new” problem. But, hopefully someone will recognize what must be a trivial issue and offer the solution.

Thanks.