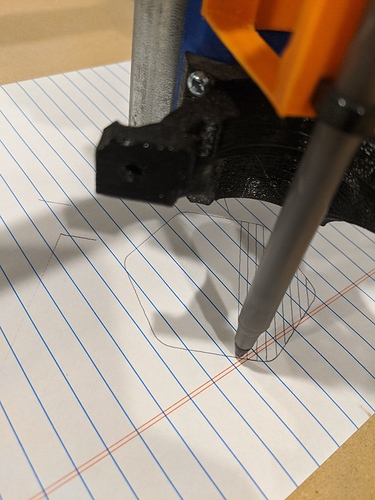

Hi everyone. I got my MPCNC up and running, and I successfully ran the test crown file with repetier-host (RH).

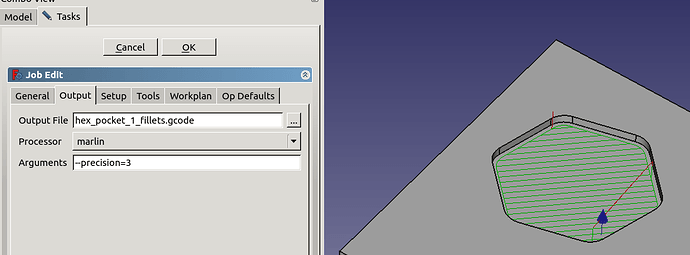

Now I’m trying to run a very simple gcode file I made in FreeCAD. I used the marlin postprocessor from this thread: Freecad marlin post processor - #2 by ByronM (because FreeCAD doesn’t have a marlin PP built in).

Here’s where I’m confused. From what I can tell, my gcode file from FreeCAD was failing because it had Z coordinates below zero, which RH…apparently doesn’t allow?

Confusingly though, my test crown gcode file has some Z-1.000 lines (when it’s cutting/plotting I guess)… and I ran that with RH! So what gives?

I found this thread: Can't go below Z0 even with end stops disabled - How to calibrate then? - Repetier-Forum which says what I found: moving up and down with the “up and down” buttons in RH, it wouldn’t let me go below Z=0, but if I manually entered the gcode command to, it would…

My conception of typical milling (and what the gcode of test crown seems to imply) is that we set our milling bit to just touch the top of the work piece, and set that to be Z=0, and then cuts will be Z < 0, and most movement will be at Z > 0. Is that not right?

If it is right, then how is it supposed to work with RH? And why did RH let me run the test crown script?

lastly, @jeffeb3 said in another thread I made:

Repetier host doesn’t trust Marlin’s coordinate system, and they foolishly don’t know about G92 Z0. You can tell RH you are at 0, with the secret

@isathomecommand.

I actually already have that as a macro in RH. But I’m confused. I see why I’d want to do that (with my pen/mill at the top of my work piece), but how does that solve the problem of RH not wanting me to go below 0? or am I just mistaken about that?

Sorry for the dumb questions,

-A guy who really wants to use his MPCNC

you are a hero!

you are a hero! as far as debugging I’ve done in my life, this isn’t too bad. At least this has a fast REPL…

as far as debugging I’ve done in my life, this isn’t too bad. At least this has a fast REPL…