So, what about static from the vacuum? I seem to remember seeing it ran perfect without extension, but not with, or is that gone now? Do you always run the vacuum? If so, please try with out, and run all wiring away from it. (I will say this though, it seems to perfect for interference)

Also, have you tried in the middle or end of your table? Just in case there is something odd?

Do the 2 or 3 drawing in the middle or end is what I am saying.

@jeffeb3 multiple beers!!!

@RockinRiley no vacuum or router during the drawings

@vicious1 12v 16.7A (because I had one laying around) professional power supply.

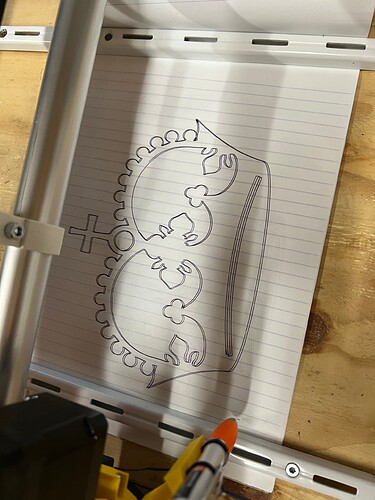

In the middle it’s much cleaner. (Somehow the paper probably got a bit greasy that’s why the pen didn’t hit everywhere

But still off.

Could it be inferior GT2 belt? (Rubber with aramid fiber)

I assume if it is stretched etc it stil should travel the same amount forward as backwards?)

Bad belt would have a horrible, but repeatable spot. Not bad belt.

Unless your belt does not match your pulleys. Did you source them together? GT2?

@vicious1 source them together is a large word  .

.

They are both gt2 from AliExpress they fit perfectly so no reason to doubt them I think.

man it seems odd that it got better. It is not as far off.

What i was looking for was if it was hitting something on return to zero. It is still off, but the fact that is a smaller margin of error is throwing me off.

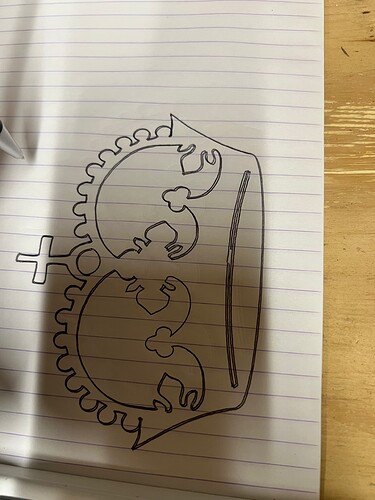

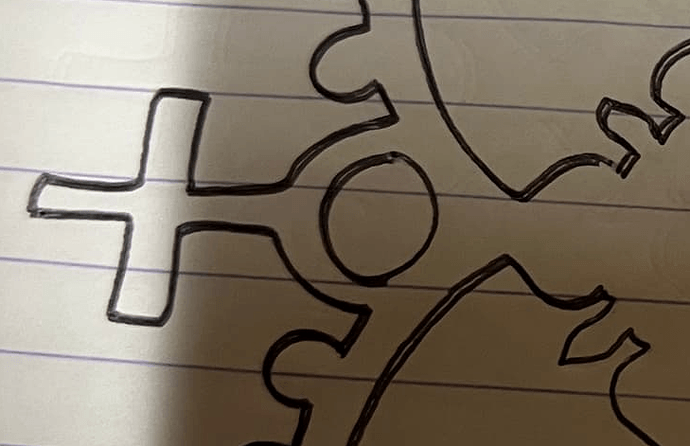

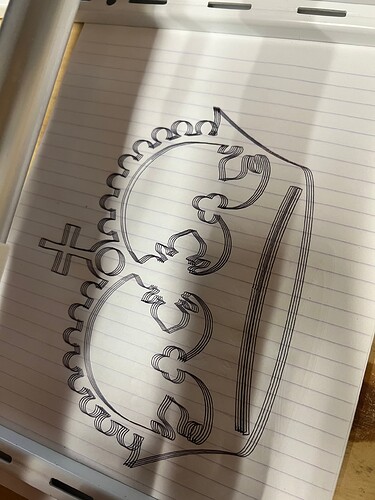

It should be round and the cross from what I understand should taper slightly inward to the center for each arm, or at least that’s what mine looks like. lol.

It is not a perfect circle.

Could this be related to the soft stops? Maybe see if M211 S0 changes it?

Did you try restting your eeprom settings with M502/M500. If you are worried about losing something, M503 writes out almost everything you can change.

Did a M502-M500 (and a new pen)

Did NOT put the correct step/mm in so everything is out of the box firmware marlin 2.1.1

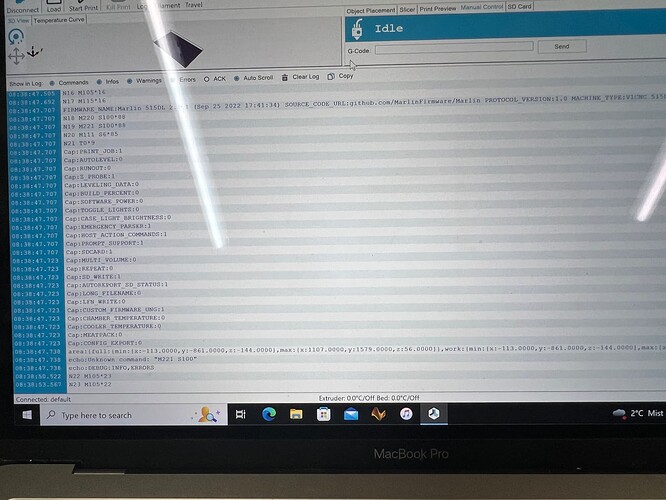

M115 result:

From tft

Then did the same thing from repetier (only lowered the Z -5mm)

So there is no difference from repetier or the tft.

BiQu support asks “ Or do you have a setup current or a configuration file correction”

I assume there is nothing in the firmware that does that?

I got a response from Biqu:

“Through verification and discussion with colleagues, it is believed that the setting relationship of your firmware step value leads to this phenomenon.”

Which sounds a bit odd?

(Or does it make sense to anyone?)

And now even more wierd:

I decided to take the Y motor, put a stripe in it, mark location, jog it forward and backwards to see if it would come back @ the same position.

No Mather what I do it comes back to the same spot.

Even when I adjusted Y to do 50 steps per mm should give an offset of 50x1.8degrees stil on the same spot

When I print the crown it returns perfectly on the spot.

For me this means it pully/belt related?

I’m going to order some new belts and pullys from the same source to see if it solves the issue

If it was me, I wouldn’t order from the same source again. I’d get them from @vicious1 or possibly amazon. This is what I bought and seems to work fine.

https://www.amazon.com/dp/B097T4DFM6?psc=1&ref=ppx_yo2ov_dt_b_product_details

https://www.amazon.com/dp/B07K8DTDLF?psc=1&ref=ppx_yo2ov_dt_b_product_details

@Silar Sure not going to source them from the same source

Amazon Europe is a bit different then Amazon US so I’ll try to source it locally.

@vicious1 Clicking the link I see I have ordered and used 20 Teeth pullies instead of 16 Would that make a difference?

If you scroll back you see me typing it has to be a simple thing………

Embarrassing mode on > shame hat on and I will be sitting in the corner for a few weeks:

I got 6mm pulleys😰.

Assumption is the mother of all *******

It just makes no sense to me that it ONLY moves between crowns, never in the middle of one. I sent you a gcode with two crowns back to back…and it still ONLY moved between crowns.

I am seriously at a loss here.

Any other issue would be random, or stack up.

I am really starting to wonder if your belt being so far out of line is causing you to skip a step at 0,0. To test that, I had you move it away from 0,0. That would not explain why you were also skipping steps on X.

But now for some reason you are only having issues on the Y axis.

Are your belts too tight. If you pluck them do the sound like a bass guitar (too tight)? The other thing would be to power down completely and swap the driver modules X to Z ect (did you bend the pins like you are supposed to)?

That has to be it.

I would bet money on it.

But why??? Need to dig and/or submit a bug report.