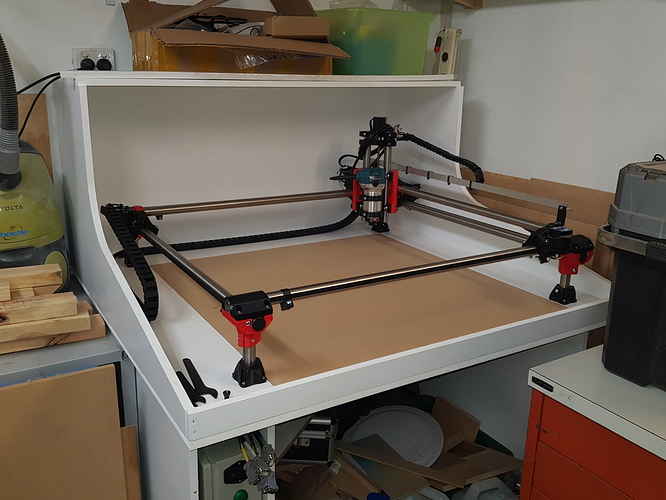

So I’m well and truly into my Primo Build… So far I have build a cabinet for it to sit on, have built and assembled the printed parts, stainless tube, motors, wiring, limit switches, and spindle( makita router)… I have decided to fully contain my CNC, so at this stage the parts are cut just not assembled… I have a old electrical switchboard that will house all of the electronics which I have started to wire up just waiting on my RAMBo v1.4 board to arrive…Have to say I’m super impressed by the design… the attention to detail is impressive… love it… can’t wait to get cutting…

Clean looking rig! But no worries, you’ll soon get it dirty. ![]()

Makes me wonder if Ryan has a count of how many countries his designs have been built in? Must be very satisfying! ![]()

Hi Sean. Nice looking setup you got there.

Mine was built in Panama

Now that white table looks verrry nice - he says making a note to file.

Did you source all the bits “locally” or buy one of Ryan’s kits?

Oh and cheers from the Sunshine Coast!

I tried for weeks to buy from Ryan but parts were not available. hopefully i will be able to “tip” him and his design… I could have got some parts but due to the weight postage to Australia was pretty high… Stainless tube was from a local supplier, belts and pulleys were from a online shop… Rambo 1.4 has been ordered from online store but still waiting… the build for me has been easy… getting my head around the programming will be the challenge…

Since you don’t mention ‘painted’ I’m curious if it is or if it’s some type of synthetic material?

Hello, no just went the easy cheaper option of MDF ( medium density fibre) board… Seeing as though I have already used 4 and a half sheets and haven’t even fired it up… ideally I would have used plywood varnished but $$$… How have others set up there MPCNC’s??

Thanks, was curious and couldn’t tell from the pix. My burly’s on a plywood base mounted on a wheel equipped cart but will likely change. I’d like to be able to take advantage of economical MDF for things like signs and some carvings but will probably need an enclosure and more effective dust control first.

Thats my thinking for the enclosure, will be ducting through a vacuum hose for a dust boot as well as a 100mm dust extraction port… would like to be able to do other things in my shed whilst the router is running, hoping it will reduce the noise level as well…

EXACTLY! ![]()

That is why I dont do mdf mine is in the basement and I’m still cleaning after 6 months so no MDF for me at least for now  I have been told the machine goes to the garage before that happens again or

I have been told the machine goes to the garage before that happens again or

I was thinking about this the other day. How is mdf different than just thick, solid cardboard?

My guess would be the binding agent used and MDF being formed with high heat/pressure that I don’t believe is the case with cardboard.

One thing that seems consistent is the mention of nasty dust by anyone who’s cut MDF.

MDF is a wonder material, and it’s pretty much the same as cardboard - just a bunch of wood fibres and glue really, If you glued your cardboard together under the same pressure you could probably call it MDF.

It does generate rather fine dust. Having said that and notwithstanding the carcinogenic effects of breathing formaldehyde long term, it’s not really any more harmful than lots of other kinds of wood dust.

Wood dust generally should not be inhaled! I could write a thesis about how I’m a bit paranoid because my brother-in-law died of mesothelioma, or my father’s asthma or even my own sinus reactions to the stuff, but others have done a much better job. Besides, I’m more paranoid about wood dust because my workspace has two rather large doors opening into a living area of the house, and letting any dust escape would lead to a painful if not lingering demise!

For a real good time, go here: http://billpentz.com/woodworking/cyclone/index.php

Don’t be alarmed, just take as many precautions as you can - electricity and lasers and fast spinning things are dangerous too.

Mine looks exactly like yours minus the enclosure and the drag chains. ![]()

MDF is similar to chip board, except chip board is made from larger bits and will fracture… MDF is very solid and pretty strong… the only problem is its dust from cutting is so fine it goes everywhere and is not very good for your lungs, hence the full enclosure with dust extraction…