We got the roof and two full sides mounted today, just one side and the front to do, but I noticed I’d put the sides to the doors on wrong, so I’ll be taking those apart and redoing them. Next step is a trip to the local big orange box to get 2x6s and plywood…

Shop progress.

Spent most of Saturday digging out the rest of the furniture and all the aquarium equipment in the shop. I put it all on facebook and was able to sell everything but the table and chairs.

The front half of the shop is a lot more useable now.

And the 3d printer now has a new home closer to the server rack. I still have a few boxes and buckets to go through.

Woohoo. The last of the excess furniture sold over the weekend… Then my wife told me that all teachers had to remove non-school furniture from their rooms SMH.

So now, I have a small pile of her stuff: two chairs, a small table and a roll of carpet. Luckily it can be piled up so that it doesn’t take up too much room in the shop.

The pile of stuff to go through is getting smaller and smaller.

For comparison, this is what that side of the shop looked like when we moved in:

I’ll try to get some more pictures of actual projects soon. The next plan of attack is to design/build the workbench and cabinets on the rest of the East wall where the TV currently sits. I want to get the TV and electronics into an enclosure so they stop collecting dust.

It’s like magic your new shop keeps getting bigger on the inside!

No real updates on the shop itself, but I finally finished a project that’s been sitting in the corner for a few months.

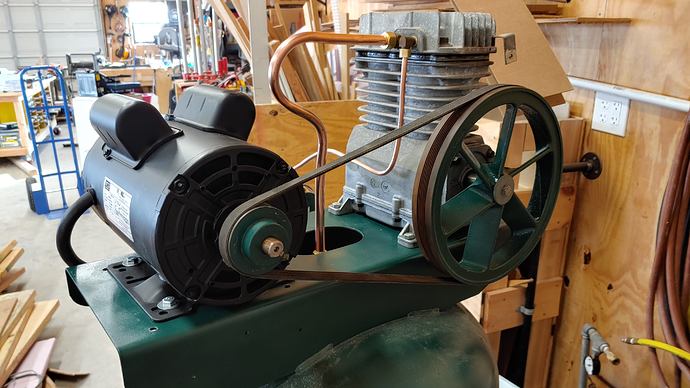

I acquired this air compressor pump over a year ago and recently picked up a tank for free from a fellow member of this board. I’ve been slowly picking up parts for the compressor over the last few months as I had nothing. The check valve on the tank was bad and needed replacing. There was no pressure switch. The pipes I had where the wrong length… etc. etc.

After a lot of research, I recently figured out what size motor I needed for the pump. I saved up some money and pulled the trigger last week. The day the motor shows up at the house, a similar sized one shows up on Facebook for $50  Oh well. I’d rather have the new motor.

Oh well. I’d rather have the new motor.

This morning I went to Home Depot with a laundry list of parts I needed to finish the build. I also had to add a 220V outlet to the shop as it didn’t have one. Copper tubing, brass fittings, power cable, outlet, plug, breaker, romex… bolts.

I spent the day in the shop modifying the tank to put the pump on the left side and the motor on the right and plumbed and wired everything.

The pump is rated for 135 psi. I have it set to turn off around 130. There was some belt squeaking and I finally got that fixed by using a spreader to tighten the belt on the pulleys by pushing the motor away from the pump just a ‘bit’ more.

The one last thing I have left to do is to re-tighten the brass fitting going into the tank. At max psi, you can just hear a slight hiss of air coming out of the compression fitting.

I give you… Frankenstein’s Compressor.

Can I call it Frankenstein and let pedantic people correct me?

Francompressorstein.

You could, but I’d laugh at you.

The friend of mine that does the woodworking for a living that bought the 5’x10’ CNC is running out of room in his shop. He called me up and told me to come get some stuff.

Today I ran over and picked up this 8’x2’ workbench complete with chop saw already installed for free.

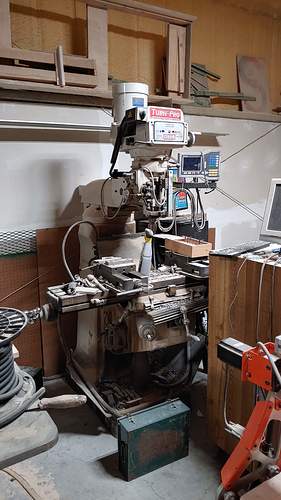

While I was there, we discussed this guy, and he’ll be coming home to me next weekend… not free, but a ridiculously cheap price. He also has a very very large Leblond Lathe he wants to get out of his shop, but it’s way too big for anywhere I plan on putting one. It’s a 9"x48" mill. The motor is a 3hp 3 phase. I’ll need to buy a phase converter or a VFD for it. It’s complete with DRO and automatic feed.

Lucky!

The gantry still hasn’t come in yet, but I went and picked up the mill on Saturday. It’s sitting on the trailer under the carport.

Driving home with this thing in tow had the pucker factor set to 11. These things are notoriously top heavy even with the headstock flipped upside resting on the knee.

Here’s a picture of it sitting on the trailer you can gawk at while waiting to hear if I drop it on a toe getting it off the trailer

I picked up a bottle of simple green so I can give it a good cleaning once it’s in the shop.

FWIW, I was taught never to use anything like simple green on machined sufaces. I’d be afraid of it finding it’s wasy between the gibs and the ways and other such locations and eventually inducing corrosion. I think something like mineral spirits is a safer option.

Nice score, by the way. I would have no place to put such a machine, but I’m a little jealous anyway. 8^)

From what I’ve read the military has banned its use around aircraft due to its potential for finding its way between surfaces and leading to corrosion.

I think that may be a fairly large group! ![]()

Upgrade!

What a beast. That really adds some expectations to your projects from now on. I hope to see some great pieces out of your workshop from now on.

Sooooo, I have used one of these to mill HD foam.  I needed the DRO to make accurate pockets. Such a waste of a beast like this, still fun trying to make sure I always turned the knobs the right way.

I needed the DRO to make accurate pockets. Such a waste of a beast like this, still fun trying to make sure I always turned the knobs the right way.

Is that a CNC control box on it or a digital position indicator?

Interesting. I’ll have to read up on that. Maybe I could spray it on the rag first and then wipe it down?

I don’t plan on using it on the machined surfaces but to remove the gunk off the painted parts of the machine.

That’s just a DRO. No CNC on this machine… yet?!? Long term ideas/goals on that.

Simple Green is not on the “approved” list of cleansers for the aircraft I work on, but I don’t know about the militaries rules. I understand that it does have citric Acid in it. While citiric acid is only very mildly corrosive, it can probably do damage over time if left in crevices. They do make a non-corrosive “extreme” version now which is probably safer.

I’m no machinist, but I’ve had the opportunity to hang around and learn a little from one while he worked. His take was that the ways should be treated like an altar. All the heavy cast iron in a lathe or mill is just a foundation and exists strictly to keep the “altar” flat and true. The acolyte should anoint the altar with holy Way Oil daily, after which offerings of swarf are appropriate. It would be blasphemous to use a strong solvent (brake cleaner) or corrosive cleaner (Simple Green, oven cleaner), on the “altar” or risk desecrating it with unholy abrasives (shudder…).

This was all a bit in jest of course, but it was clear watching him work that he took it seriously too, and it was obviously a sufficeintly memorable way of putting it to stick with me. 8^)

Noted.

I’ll spray the Simple green on the rag and use it to wipe off the gunk on the paint only. This machine has a one-shot oiler that will sufficiently lubricate all ways prior to each use.

Dang, I’ve been saying for years my garage is too small… Looks like when I buy a shop I’ll want three phase too.

The largest erector set I’ve ever bought showed up at my doorstep today. Took a pallet jack and lift gate to get it up the driveway.

I spent my lunch break emptying the crate and bringing the parts into the shop.

Hydrogen induced brittlement is why we stopped using it. It’s also corrosive to rubber hoses.